UV photo-oxygen catalytic equipment

Air Pollution Control Equipment

UV photo-oxygen catalytic equipment

Zhengzhou Puhua Technology's UV photo-catalytic oxidation equipment boasts high technical expertise, delivering stable treatment effects for organic waste gases. It is harmless to humans and achieves a sterilization rate of over 99.9% for various bacteria in the air. Furthermore, it can oxidize and decompose harmful components in polluted air into harmless substances in a short period of time.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

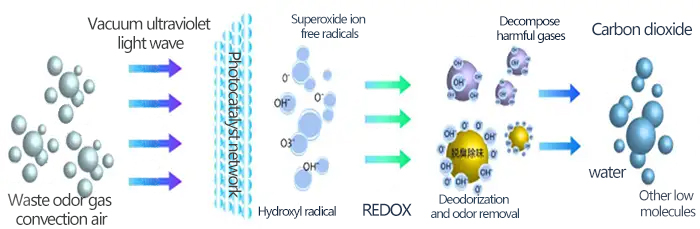

1、 Process Principle of UV Photooxygen Catalytic Equipment

Organic waste gas enters UV photo-oxygen catalytic equipment and undergoes coarse filtration, ozone oxidation and UV light cracking to achieve decomposition effect;

The decomposed material is adsorbed by the activated carbon plate at the end to achieve the purpose of purification.

UV lamp tube inspection

2、 Process Flow of UV Photooxygen Catalytic Equipment

Img alt="UV photo-oxygen catalytic equipment process flow" src=“ https://www.zzphkj.com/uploads/allimg/211014/2-211014145935410.webp "/>

The organic waste gas enters the UV photo-oxygen catalytic equipment under the action of the induced draft fan. The coarse filter baffle initially filters the large particles in the gas to reduce the treatment pressure of the next process.

The filtered organic waste gas enters the oxidation decomposition zone, is forced to be oxidized by ozone and decomposed into other substances, and then enters the UV light cracking zone for further decomposition to change the molecular structure, so as to recycle.

The gas after multiple decomposition is absorbed by activated carbon and discharged to purify the organic waste gas.

Auxiliary equipment such as scrubber and activated carbon tank can be added to assist in the treatment of organic waste gas according to the actual production situation of customers.

How to Treat Organic Waste Gas by UV Photooxygen Catalytic Equipment

3、 Performance characteristics of UV photo-oxygen catalytic equipment

UV photo-oxygen catalytic equipment integrates paint mist filtration, oxidation, cracking and adsorption, with higher treatment efficiency for organic waste gas with small air volume and low concentration;

The specific gravity of each treatment procedure can be flexibly adjusted according to the actual composition of organic waste gas, so the purification effect is better;

The equipment is an integrated collection of multiple organic waste gas treatment methods, which is easy to install and operate;

The overall power of the equipment is small, the floor area is small, the operation is simple and the later operation cost is low.

4、 Application scope of UV photo-oxygen catalytic equipment

UV photo-oxygen catalytic equipment has a wide range of application. It can effectively treat and purify VOCs organic waste gas, non-methane hydrocarbon, eight malodorous substances (ammonia, hydrogen sulfide, carbon disulfide, methyl mercaptan, methyl sulfide, dimethyl disulfide, trimethylamine and styrene), benzene, toluene, xylene and other waste gases, and has obvious effects on the treatment of various malodorous waste gases, decaying waste gases, painting waste gases, spraying waste gases, electrophoresis waste gases, electroplating waste gases, printing and dyeing waste gases, biopharmaceutical waste gases, waste water, sewage, odor waste gases, sludge odor, etc. UV photo-oxygen catalytic equipment can treat the waste gas unsuitable for plasma equipment, such as spray painting waste gas, spraying waste gas, chemical waste gas, waste gas containing gasoline and alcohol, waste gas containing Tianna water, waste gas from paint plant, waste gas from fertilizer plant, etc.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Activated carbon+catalytic combustion equipment (RCO)

View details

Zeolite runner+Catalytic Combustion Equipment (RCO)

View details

Regenerative Combustion Decomposition Equipment (RTO)

View details

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

View details

Resin desorption+condensation recovery equipment

View details

Industrial electrostatic fume purifier

View details

Wet electrostatic oil fume pre-filtration device

View details

Cooking oil fume purifier

View details