Resin desorption+condensation recovery equipment

Air Pollution Control Equipment

Resin desorption+condensation recovery equipment

Puhua Technology's resin adsorption and desorption + condensation recovery process is a VOCs organic waste gas treatment technology that combines adsorption and condensation methods. This process fully utilizes the advantages of both methods, featuring high purification efficiency, stable treatment indicators, low resin loss, and long service life. Under normal conditions, the resin can be used for more than 5 years, with an annual resin replenishment rate of less than 10%, and the treatmen

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

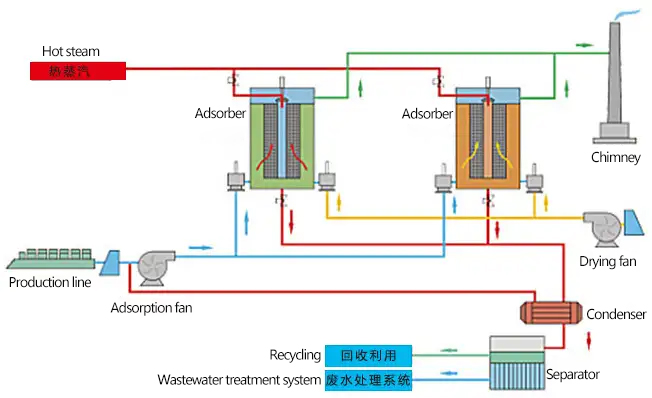

I. Principles of resin adsorption and desorption+condensation recovery

Resin adsorption and desorption+condensation recovery is to use granular or fibrous resin to adsorb molecules of organic components in the waste gas. When the adsorption reaches a certain saturation, stop adsorption, start to use saturated low-pressure water vapor to heat and adsorb saturated resin, activate and gasify the adsorbed organic components, and then desorb from the resin. The recovered resin can re-absorb gas molecules of organic waste gas. At the same time, the gas desorbed from the organic component is condensed, so that its liquefaction and water are automatically separated and recovered.

Click ViewCase: medical industry waste gas treatment resin adsorption condensation recovery

Click ViewCase: medical industry waste gas treatment resin adsorption condensation recovery

2、 Resin adsorption and desorption+condensation recovery process

Strong>Pretreatment adsorption:The exhaust gas is pressurized by the fan into the resin adsorption tank. The organic components are adsorbed when penetrating the resin layer. The adsorbed purified gas is discharged after meeting the standard.

Strong>Desorption regeneration:The resin is desorbed and regenerated with steam. The desorption steam enters from the top to heat the resin bed to desorb organics. The desorption resin has high humidity and temperature, so it is necessary to purge air into the absorber to cool and humidify the resin adsorption bed.

Strong>Condensation recovery:The mixed steam generated by desorption is recycled by the condenser to recover the liquid mixture. The mixture can be recycled by gravity stratification, distillation, rectification, etc.

3、 Components of resin adsorption and desorption+condensation recovery equipment

The resin adsorption and desorption+condensation recovery equipment of Parkway Technology includes gas adsorption module, liquid separation circulation module and steam supply unit. The gas adsorption module consists of a capture tower, a dry filter and a parallel resin adsorption tank. The parallel resin adsorption tank comprises a tank body, a spray head and a multilayer adsorption assembly. The multilayer adsorption assembly comprises a first grid, a first separation screen, a first resin layer, a second grid, a second resin layer, a second separation screen and a gravel layer stacked from bottom to top. The liquid separation circulation module includes condenser, gas-liquid separator, liquid-liquid separator and liquid storage tank.

Img sr="/static/upload/image/2020906/1662451593190464. webp" alt="resin desorption+condensation recovery equipment webp" _propertydelete="width,height,style" border="0" vspace="0" style=""/>

Span style="color: # 00B0F0;">Click View4、 Characteristics of resin adsorption and desorption+condensation recovery

High process level, long service life and purification efficiency up to 99%;

Stable performance, low energy consumption, small land occupation and easy maintenance;

Intermittent or continuous operation;

Organic liquid can be directly recycled without secondary pollution;

Easy desorption and regeneration, saving operation cost.

5、 Application scope of resin adsorption and desorption+condensation recovery

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Activated carbon+catalytic combustion equipment (RCO)

View details

Zeolite runner+Catalytic Combustion Equipment (RCO)

View details

Regenerative Combustion Decomposition Equipment (RTO)

View details

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

View details

Resin desorption+condensation recovery equipment

View details

Industrial electrostatic fume purifier

View details

Wet electrostatic oil fume pre-filtration device

View details

Cooking oil fume purifier

View details