Zeolite runner+Catalytic Combustion Equipment (RCO)

Air Pollution Control Equipment

Zeolite runner+Catalytic Combustion Equipment (RCO)

The zeolite wheel + RCO catalytic combustion equipment is a practical process currently applied in the field of organic waste gas treatment. It adopts three continuous procedures: adsorption, desorption, and cooling, with adsorption and desorption occurring simultaneously. The zeolite wheel first adsorbs, collects, compresses, and concentrates organic waste gas, and then desorbs the high-concentration waste gas molecules from the zeolite wheel and sends them into the catalytic oxidation furnace

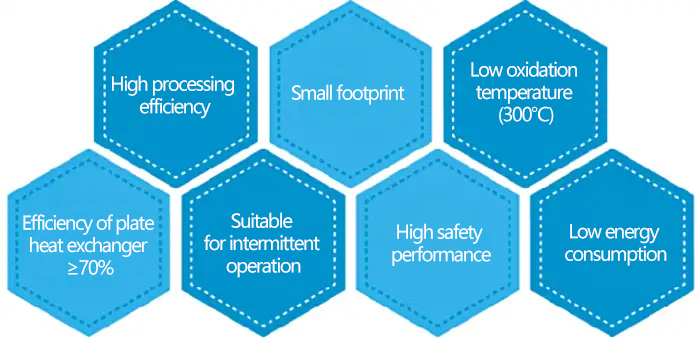

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Process Principle of Zeolite Runner+Catalytic Combustion Equipment (RCO)

First, use the zeolite runner to absorb and compress the volatile organic waste gas (VOCs) to increase the concentration;

Desorption of high-concentration waste gas molecules and sending to catalytic oxidation furnace for flameless combustion, decomposition into CO2 and H2O, so as to purify organic waste gas.

2、 Process Flow of Zeolite Runner+Catalytic Combustion Equipment (RCO)

The volatile organic waste gas (VOCs) with large air volume and low concentration is filtered by the filter under the action of the induced draft fan, and then enters the zeolite runner for adsorption and concentration. The clean air after adsorption and purification is discharged into the atmosphere through the chimney.

The electronic control system controls the catalytic oxidation furnace to start heating and preheat the precious metal catalyst. The heated high temperature gas is cooled by the heat exchanger and then adjusted to 100-200 ℃ by air mixing. The zeolite runner rotates slowly (3~8r/h). When the runner in the adsorption zone rotates to the desorption zone, it is desorbed at 100-200 ℃ in the desorption zone. The desorbed high concentration organic waste gas is preheated by the heat exchanger and sent to the catalytic oxidation furnace. Under the action of the precious metal catalyst, the flameless combustion occurs at 250-300 ℃. The organic waste gas is oxidized and decomposed into CO2 and H2O. The purified air is discharged through the chimney at high altitude.

Zeolite molecular sieve has stronger adsorption capacity on organic waste gas and better filtration effect;

Decrease of pressure generated by absorption of VOCs by zeolite molecular sieve can greatly reduce power consumption;

The concentration of organic waste gas can reach 15-20 times, with better treatment effect;

Desorption of organic waste gas with ignition point of about 200 ℃, wider application than activated carbon;

Longer service life of zeolite molecular sieve;

Zeolite molecular sieve occupies less space and the system setting is more flexible;

Pre-group and modular design is adopted for the overall system to provide continuous and unmanned control mode;

System automation control, single button start, simple operation, and human-computer interaction interface, monitoring important operation data.

4、 Application scope of zeolite runner+catalytic combustion equipment (RCO)

Strong>Mainly applicable to:various organic waste gas purification treatment generated during production and operation of petrochemical industry, surface coating industry, wood processing industry, semiconductor manufacturing industry, electronic component manufacturing industry, printing industry, packaging material manufacturing industry, coating manufacturing industry, chemical material manufacturing industry, pharmaceutical industry, metal forging industry, paper industry, printed circuit board manufacturing industry, photoelectric material and component manufacturing industry, automobile manufacturing industry, aviation industry, etc. Good treatment effect of organic waste gas such as benzene, methylbenzene, xylene and non-methane total hydrocarbon required by current key environmental protection requirements.

Strong>Applicable conditions:Low concentration, medium air volume, temperature lower than 50℃, humidity lower than 90% RH;

Strong>Applicable organic waste gas component:benzene, toluene, xylene, alcohol, ketone, aldehyde, partial ester, etc;

Strong>Not applicable for organic waste gas components:UV paints, curing agents, high boiling point polymers, halogens and their compounds.

5、 Specification of Zeolite Runner+Catalytic Combustion Equipment (RCO)

| Product model | Treatment air volume (m3/h) | Preheating temperature ℃) | Equipment resistance (pa) | Handling efficiency (%) | Flange inlet diameter (mm) | Flange outlet diameter (mm) | Overall dimensions (mm) |

| PH-RCO-2000 | 2000 | 200-300 | 350 | ≥95 | DN200 | DN200 | 2200x1660x2150 |

| PH-RCO-5000 | 5000 | 200-300 | 350 | ≥95 | DN300 | DN300 | 2860x1810x2300 |

| PH-RCO-10000 | 10000 | 200-300 | 350 | ≥95 | DN400 | DN400 | 3380x1880x2580 |

| PH-RCO-15000 | 15000 | 200-300 | 350 | ≥95 | DN500 | DN500 | 3600x1980x2860 |

| PH-RCO-20000 | 20000 | 200-300 | 350 | ≥95 | DN600 | DN600 | 4200x2050x3270 |

| PH-RCO-25000 | 25000 | 200-300 | 350 | ≥95 | DN650 | DN650 | 4530x2260x3850 |

| PH-RCO-30000 | 30000 | 200-300 | 350 | ≥95 | DN700 | DN700 | 5050x2350x4550 |

| PH-RCO-35000 | 35000 | 200-300 | 350 | ≥95 | DN750 | DN750 | 5850x2590x4850 |

| PH-RCO-40000 | 40000 | 200-300 | 350 | ≥95 | DN800 | DN800 | 6350x3050x4950 |

6、 Engineering Case of Zeolite Runner+Catalytic Combustion Equipment (RCO)

Img alt="Zeolite runner+Catalytic combustion equipment (RCO) product introduction" SCC=“ https://www.zzphkj.com/uploads/200713/2-200G3113TG52.webp "/>

Zeolite runner+RCO catalytic combustion equipment is installed in the spray booth of Zhengzhou customers

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Activated carbon+catalytic combustion equipment (RCO)

View details

Zeolite runner+Catalytic Combustion Equipment (RCO)

View details

Regenerative Combustion Decomposition Equipment (RTO)

View details

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

View details

Resin desorption+condensation recovery equipment

View details

Industrial electrostatic fume purifier

View details

Wet electrostatic oil fume pre-filtration device

View details

Cooking oil fume purifier

View details