Regenerative Combustion Decomposition Equipment (RTO)

Air Pollution Control Equipment

Regenerative Combustion Decomposition Equipment (RTO)

The Regenerative Thermal Oxidizer (RTO) designed and produced by Zhengzhou Puhua Technology is an organic waste gas treatment equipment. Compared with traditional catalytic combustion and direct thermal oxidizers (TO), the RTO features high thermal efficiency (≥95%), low operating costs, and the ability to handle large volumes of medium and low-concentration waste gas. When the concentration is slightly higher, it can also perform secondary waste heat recovery, significantly reducing production

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

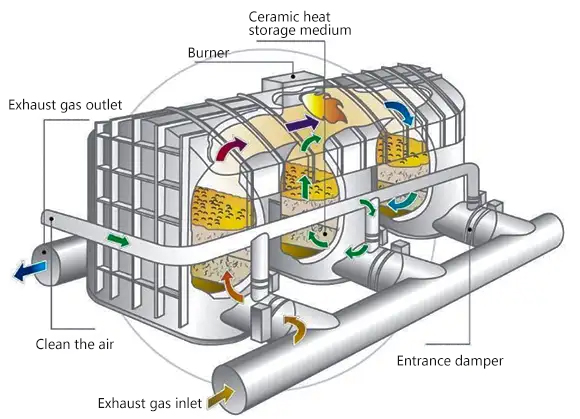

1、 Process Principle of Regenerative Combustion Decomposition Equipment (RTO)

The collected organic waste gas is directly sent to the heat storage chamber by the fan through the pipeline and heated by burning the natural gas;

When the organic waste gas is heated to above 760 ℃, it is oxidized and decomposed into CO2 and H2O to realize purification treatment.

2、 Process Flow of Regenerative Combustion Decomposition Equipment (RTO)

The organic waste gas is collected and enters the combustion chamber through the first heat storage chamber. The ignited natural gas is heated to above 760 ℃ and oxidized into CO2 and H2O for purification. The purified high temperature gas is discharged from the second heat storage chamber, and the heat storage chamber is heated at the same time.

When the second heat storage chamber is heated to the set temperature by the high temperature gas, the switching valve opens, the organic waste gas enters from the heat storage chamber, is oxidized and decomposed at high temperature, and is discharged from the first heat storage chamber, so as to heat the first heat storage chamber, so as to realize the purification of the organic waste gas under the condition of making full use of the heat energy. The ceramic heat storage body insulation materials selected for RTO equipment can save a lot of money)

The RTO system of the three heat storage chambers is similar to this principle. More than one heat storage chamber enters the cleaning state, which can effectively prevent the escape of a small amount of organic waste gas that is not completely decomposed, and the treatment effect is better.

Img alt="Regenerative Combustion Decomposition Equipment (RTO) Engineering Case" SCC=“ https://www.zzphkj.com/uploads/200713/2-200G3114954Y7.webp "/>

Example: Three-room RTO equipment is installed in the plant of chemical customer

3、 Performance Characteristics of Regenerative Combustion Decomposition Equipment (RTO)

RTO system is suitable for treatment of organic waste gas with small air volume and high concentration;

Organic waste gas with large elasticity and varying concentration can be treated;

Low sensitivity to dust can effectively improve the purification efficiency, and the purification rate is about 99%;

RTO thermal efficiency is about 95%, with less system maintenance, high operation safety and reliability;

The heat accumulator can be replaced or cleaned to completely remove organic sediments, and the pressure loss of the unit is small;

The removal rate of VOCs of two-chamber RTO device is 95% - 98%, and the removal rate of VOCs of three-chamber RTO device can reach more than 98%.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Activated carbon+catalytic combustion equipment (RCO)

View details

Zeolite runner+Catalytic Combustion Equipment (RCO)

View details

Regenerative Combustion Decomposition Equipment (RTO)

View details

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

View details

Resin desorption+condensation recovery equipment

View details

Industrial electrostatic fume purifier

View details

Wet electrostatic oil fume pre-filtration device

View details

Cooking oil fume purifier

View details