Industrial electrostatic fume purifier

Air Pollution Control Equipment

Industrial electrostatic fume purifier

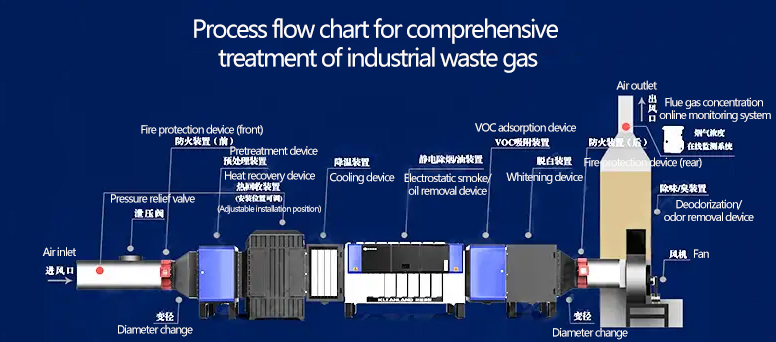

Industrial electrostatic oil fume purifiers, also known as industrial electrostatic oil fume removal equipment, are designed by Puhua Technology to treat and recycle exhaust gas, oil fumes, and oil mist generated during industrial processing. These exhaust gases, oil fumes, and oil mist are characterized by large volumes of smoke, high temperatures, and high concentrations. Puhua Technology's electrostatic oil fume purification equipment boasts high stability, ease of use and maintenance, a

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

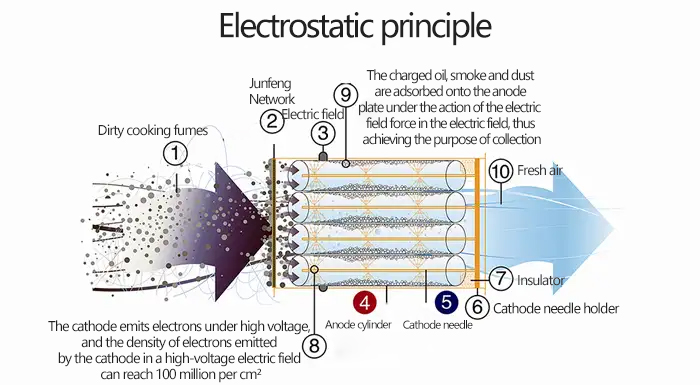

1、 Process principle of industrial electrostatic fume purifier

Electrostatic oil fume purification equipment captures oil fume particles and dust by using electrons emitted by cathode in high voltage electric field and negative ions generated by electrons colliding with air molecules, so as to charge oil fume particles and dust;

Utilize the electric field to adsorb charged oil fume particles and dust by the anode, so as to remove oil and dust.

2、 Performance advantages of industrial electrostatic fume purifier

Good smoke removal effect: the smoke removal efficiency of industrial electrostatic fume purifier can reach 98%.

Low operation cost: Industrial electrostatic fume purifier adopts honeycomb electric field and horizontal structure, with small resistance. The resistance of the fan is reduced, and the operation cost is reduced. The equipment itself adopts high voltage control system and high voltage power supply, with high conversion efficiency and low power consumption.

Convenient maintenance: the components to be cleaned regularly are removable modular combinations, which not only facilitates the daily cleaning and maintenance of the equipment, but also facilitates the maintenance and replacement of these components.

Upgradability: the equipment adopts the combined structure of standard flange connection, so that the equipment has the upgradability. The modular purification units can be flexibly combined, and the number of units can be adjusted according to different purification treatment capacity and purification rate requirements.

Small floor area: the power supply of the equipment is combined with the equipment, and there is no need to build another power control room to save the plant area.

Continuity of operation: group power supply mode is adopted. Even if a group of electric field discharges or fails, other groups can work normally without affecting the operation of equipment and ensuring the continuity of equipment operation.

Careful design: the high-voltage power supply is designed as a unit body tightly sealed by epoxy resin, which adopts group power supply and group control, so it is safe and reliable to use.

High safety: the equipment is equipped with fire screen, fire damper, temperature detection system and fire extinguishing system to ensure safe and stable operation of the equipment.

Air flow direction: horizontal structure. When the user installs, the air duct, purification equipment and exhaust fan can be conveniently arranged transversely to facilitate layout and reduce wind resistance; At the same time, it is convenient for air balancing of the purifier, so as to improve the smoke removal efficiency.

Narrow spacing structure is adopted for cathode and anode spacing: large anode area is contained in unit volume, with small volume and good smoke removal effect.

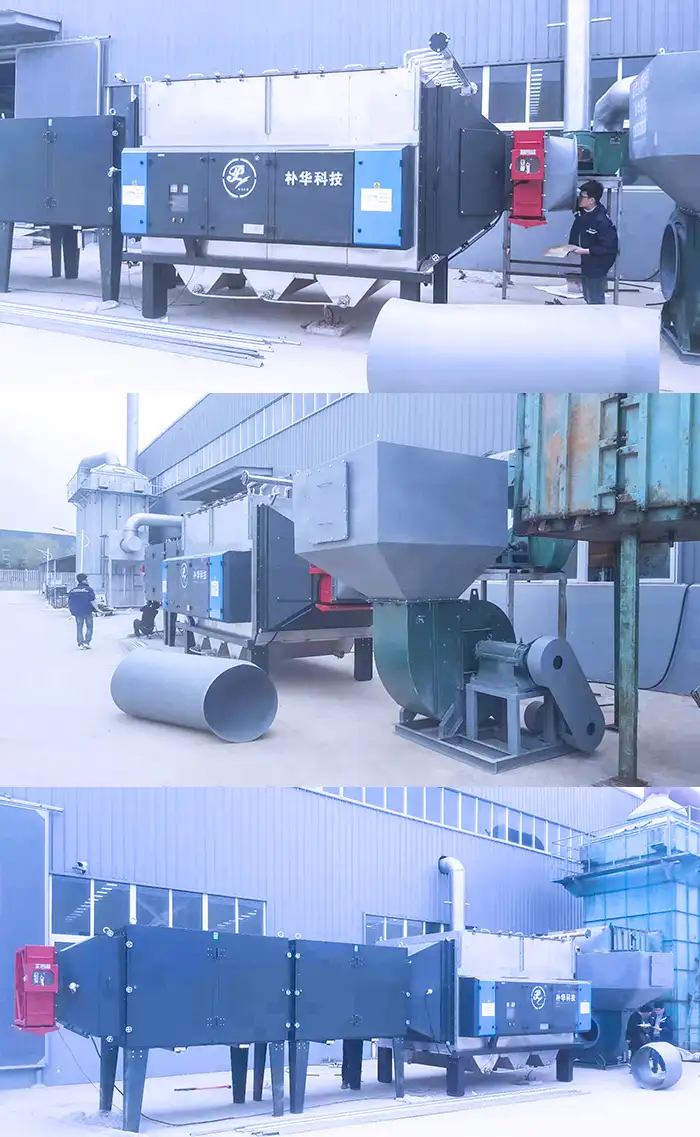

Easy installation of equipment: the equipment is light and no special foundation is required. The main equipment is installed and commissioned in the factory. Low installation cost, short time, easy to achieve the design effect.

HV and LV control: HV control circuit with chip control, intelligent LV control with PLC. Safe, reliable and intelligent operation.

3、 Specifications and parameters of industrial fume purification equipment

| model | Treatment air volume (m3/h) | Weight (kg) | Power consumption (kw) | Length, width and height (mm) |

| PH-FP-12K | twelve thousand | one thousand | three point six | 1743x2060x2560 |

| PH-FP-16K | sixteen thousand | one thousand and five hundred | five point four | 2616x2060x2560 |

| PH-FP-20K | twenty thousand | two thousand | seven point two | 3489x2060x2560 |

| PH-FP-24K | twenty-four thousand | two thousand and five hundred | nine | 4362x2060x2560 |

| PH-FP-28K | twenty-eight thousand | three thousand | ten point eight | 5235x2060x2560 |

4、 Installation site of industrial fume purification equipment

5、 Application scope of industrial electrostatic fume purifier

Exhaust gas purification of textile printing and dyeing, PVC products, metal processing, electronics, building materials and chemical industry, food processing, catering industry, hotel catering and other industries;

Oil splashing heat treatment workshop, oil mist lubrication workshop, workpiece welding workshop and olefin oil boiler emission and other industrial sites.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Activated carbon+catalytic combustion equipment (RCO)

View details

Zeolite runner+Catalytic Combustion Equipment (RCO)

View details

Regenerative Combustion Decomposition Equipment (RTO)

View details

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

View details

Resin desorption+condensation recovery equipment

View details

Industrial electrostatic fume purifier

View details

Wet electrostatic oil fume pre-filtration device

View details

Cooking oil fume purifier

View details