Activated carbon+catalytic combustion equipment (RCO)

Air Pollution Control Equipment

Activated carbon+catalytic combustion equipment (RCO)

The activated carbon + regenerative catalytic combustion (RCO) equipment designed and produced by Puhua Technology utilizes activated carbon modules to adsorb, collect, and compress volatile organic compounds (VOCs), thereby increasing their concentration. Subsequently, the high-concentration exhaust gas molecules are desorbed from the activated carbon modules and sent into a catalytic oxidation furnace (CO furnace) for flameless combustion, decomposing the organic exhaust gas into CO2 and H2O,

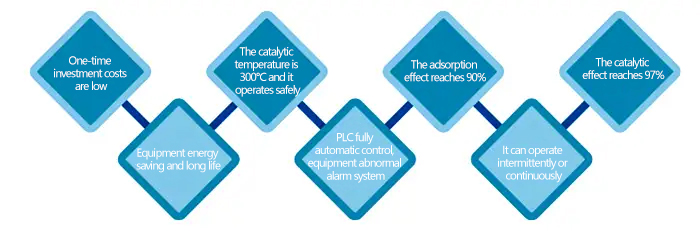

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Process principle of activated carbon adsorption+catalytic combustion equipment (RCO)

点击查看

Firstly, use the activated carbon module to absorb and compress volatile organic waste gas (VOCs) to increase the concentration;

Desorption of high-concentration waste gas molecules and sending to catalytic oxidation furnace for flameless combustion, decomposition into CO2 and H2O, so as to purify organic waste gas.

Strong>II.Process flow of activated carbon adsorption+catalytic combustion equipment (RCO)

The volatile organic waste gas (VOCs) with large air volume and low concentration is filtered by the high efficiency filter under the action of the induced draft fan, and then enters the honeycomb activated carbon adsorption module for adsorption and concentration. The clean air after being absorbed and purified by the activated carbon is discharged into the atmosphere through the chimney.

With the extension of time, the adsorption capacity of activated carbon is close to saturation. The electronic control system controls the catalytic oxidation furnace to start heating and preheat the precious metal catalyst. The heated high temperature gas is cooled by the heat exchanger and then adjusted to 100-120 ℃ by air mixing to heat and desorb the saturated activated carbon module. The desorbed high concentration organic waste gas is preheated by the heat exchanger and sent to the catalytic oxidation furnace for decomposition. (

The concentration of organic waste gas can reach 10-15 times, which is more suitable for treatment of organic waste gas with large air volume and low concentration;

It only takes 15-30 minutes to raise the temperature to the ignition temperature when the equipment is started, so the energy consumption is low;

The honeycomb catalyst impregnated with precious metal palladium and platinum is adopted, with large surface area, small resistance and high purification rate;

The system waste heat can be returned to the drying channel to reduce the power consumption in the original drying channel, and can also be used as a heat source in other aspects;

Generally, the catalyst is replaced in five years, and the support is renewable, with long service life;

The outside of the equipment is at normal temperature, with high safety and purification efficiency of over 95%;

The electric heating mode is adopted to support combustion, which is simple and convenient;

Fully automatic PLC control is realized throughout the operation process, which is convenient and reliable.

4、 Application scope of activated carbon adsorption+catalytic combustion equipment (RCO)

Support organic waste gas VOCs control of various plants: organic waste gas from painting and spraying industry, organic waste gas from printing, printing and dyeing industry, organic waste gas from refineries, organic waste gas from chemical industry, organic waste gas from papermaking industry, organic waste gas from pharmaceutical industry, organic waste gas from abattoir industry, organic waste gas from food industry, organic waste gas from sewage treatment industry, organic waste gas from metal industry, etc.

Treatment of mixed organic waste gas such as benzene, alcohol, ketone, aldehyde, ester, phenol, ether and alkane;

Large air volume and low concentration VOCs mixed waste gas treatment;

Coating of chemical industry, automobile coating, machinery, ship, household appliance, furniture, building materials and other industries;

Organic waste gas purification of printing, electronics, enameled wire, rubber and plastic products, food, printing ink and other industries;

Individual organic waste gas with high boiling point shall be treated by RCO+zeolite runner process;

For VOCs mixed waste gas containing halogens, sulfur, phosphorus, arsenic and other compounds, the pretreatment system shall be used to purify and separate the substances harmful to the activated carbon and catalyst, so as to ensure the service life of the activated carbon and catalyst and the safe operation of the system.

5、 Specifications and parameters of activated carbon adsorption+catalytic combustion equipment (RCO)

| Product Model | Air volume (m³/h) | Preheating temperature ℃) | Equipment resistance (pa) | Processing efficiency (%) | Flange inlet diameter (mm) | Flange outlet diameter (mm) | Overall dimensions (mm) |

| PH-RCO-2000 | 2000 | 200-300 | 350 | ≥95 | DN200 | DN200 | 3200x1660x2150 |

| PH-RCO-5000 | 5000 | 200-300 | 350 | ≥95 | DN300 | DN300 | 3860x1810x2300 |

| PH-RCO-10000 | 10000 | 200-300 | 350 | ≥95 | DN400 | DN400 | 4380x1880x2580 |

| PH-RCO-15000 | 15000 | 200-300 | 350 | ≥95 | DN500 | DN500 | 4600x1980x2860 |

| PH-RCO-20000 | 20000 | 200-300 | 350 | ≥95 | DN600 | DN600 | 5200x2050x3270 |

| PH-RCO-25000 | 25000 | 200-300 | 350 | ≥95 | DN650 | DN650 | 5530x2260x3850 |

| PH-RCO-30000 | 30000 | 200-300 | 350 | ≥95 | DN700 | DN700 | 6050x2350x4550 |

| PH-RCO-35000 | 35000 | 200-300 | 350 | ≥95 | DN750 | DN750 | 6850x2590x4850 |

| PH-RCO-40000 | 40000 | 200-300 | 350 | ≥95 | DN800 | DN800 | 7350x3050x4950 |

6、 Engineering case of activated carbon adsorption+catalytic combustion equipment (RCO)

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Activated carbon+catalytic combustion equipment (RCO)

View details

Zeolite runner+Catalytic Combustion Equipment (RCO)

View details

Regenerative Combustion Decomposition Equipment (RTO)

View details

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

View details

Resin desorption+condensation recovery equipment

View details

Industrial electrostatic fume purifier

View details

Wet electrostatic oil fume pre-filtration device

View details

Cooking oil fume purifier

View details