Cooking oil fume purifier

Air Pollution Control Equipment

Cooking oil fume purifier

The catering fume purifier is a new type of green and environmentally friendly product launched by Puhua Technology for kitchen fume purification and treatment. This series of products has passed the testing conducted by the testing agency designated by the State Environmental Protection Administration, meeting and even exceeding the requirements of the national environmental protection emission standard (GWPB-2000) "Catering Industry Fume Emission Standard". It can handle fumes with p

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to Cooking Fume Purifier

Cooking oil fume purifier is a new type of green environmental protection product launched by Parkway Technology for kitchen fume purification. This series of products have passed the inspection of the inspection organization designated by the State Environmental Protection Administration, and meet and exceed the requirements of the national environmental protection emission standard (GWPB-2000) - Emission Standard for Cooking Fume in the Catering Industry. The 0.1-100um particulate oil fume in the food processing industry and the particles above 0.1um in the catering industry can be treated.

Example: Field installation of fume purifier in central kitchen

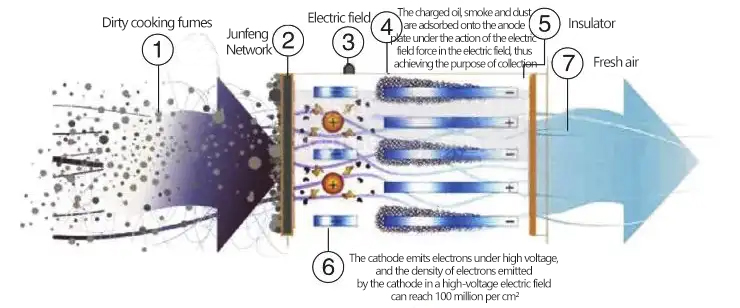

2、 Process Flow of Cooking Fume Purifier

The oil fume is sucked into the oil fume purifier by the fan, and some large oil droplets and oil particles are captured on the flow equalizing plate due to mechanical collision and retention. When the air flow enters the high-voltage electrostatic field, under the action of the high-voltage electric field, the oil fume gas is ionized and the oil mist is charged, most of which are degraded and carbonized;

A small part of tiny oil particles under the action of the electric field force and air flow of the adsorption electric field move to the positive and negative electrode plates of the electric field and are collected on the electrode plates. Under the action of their own gravity, they flow to the oil pan and are discharged through the oil discharge channel. The remaining micron level oil mist is degraded into carbon dioxide and water by the electric field, and finally the clean air is discharged;

At the same time, under the action of the high voltage generator, the air in the electric field generates ozone and removes most of the odor in the flue gas.

3、 Performance characteristics of kitchen fume purifier

Purification efficiencyHigh: honeycomb electric field, cathode and anode extremely narrow spacing structure, 95% efficient fume purification rate;

Intelligent regulation and control: non-inductive DC+pulse, special power supply, automatic regulation of control system;

Easy installation and maintenance: modular removable design, flexible combination, convenient installation, cleaning and maintenance of equipment;

High safety: high voltage power supply group control, insulator feed-through porcelain bottle, temperature detection system, fire extinguishing system, to ensure safe and stable operation of equipment;

Operation costLow: high voltage power supply+horizontal reducer structure, low power consumption, small wind resistance and low operation cost;

Flexibility can be upgraded: standard flange connection structure, purification units can be flexibly combined according to different processing capacity and purification efficiency requirements;

Pre-filter equalizing plate: protect the equipment, extend the service life by 2-4 years and extend the cleaning time by 3-5 times;

Operation continuity: the high voltage output is stable, the power is supplied in groups, and the local fault does not affect the operation of the equipment, so as to ensure the continuity of production and operation.

4、 Application scope of kitchen fume purifier

Food processing industry 0.1-100um fine oil fume treatment, cake shop, food chain processing plant, etc;

Fine particles above 0.1um in catering industry can be treated, which is applicable tofume treatmentin restaurants, central kitchens, restaurants, restaurants, steak houses, barbeque shops, large gear, etc;

Electronic processing industry, rubber industry, automobile industry, etc.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Activated carbon+catalytic combustion equipment (RCO)

View details

Zeolite runner+Catalytic Combustion Equipment (RCO)

View details

Regenerative Combustion Decomposition Equipment (RTO)

View details

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

View details

Resin desorption+condensation recovery equipment

View details

Industrial electrostatic fume purifier

View details

Wet electrostatic oil fume pre-filtration device

View details

Cooking oil fume purifier

View details