DMC single-unit pulse bag-type dust collector

Industrial Dust Collectors

DMC single-unit pulse bag-type dust collector

The Puhua Technology DMC standalone pulse bag filter adopts an integrated structure and a pulse automatic spraying and blowing ash removal system. With its compact design, reasonable layout, and high dust removal efficiency, it is widely used in numerous small and medium-sized dust workshops.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to single-unit bag dust collector

DMC single-unit pulse bag-type dust collector designed and produced by Parkway Technology is one of the representative bag-type dust collector equipment. Polyester fiber needled felt is used as the filter bag material of the dust collector under normal circumstances. This kind of filter bag has high strength, good elasticity, heat resistance, corrosion resistance, low moisture absorption, large filtration wind speed and high dust removal efficiency.

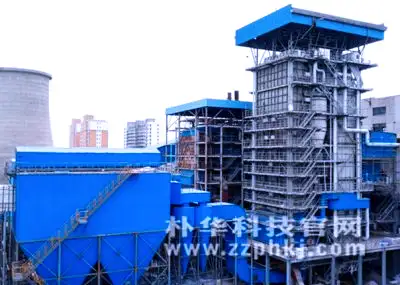

DMC single-unit pulse bag-type dust collector adopts integrated structure and pulse jet blowing dust removal system to realize dust removal and purification. The filter bag of dust collector can also be flexibly selected according to the actual smoke and dust conditions. With strong applicability, the filter bag has been widely used in boiler dust removal, furnace dust removal, waste incineration flue gas dust removal, workshop dust purification and material dust recycling and utilization fields in electric power, metallurgy, building materials, chemical industry, food, pharmacy, tobacco and other industries.

2、 Equipment performance of single bag-type dust collector

The dust removal efficiency of DMC single-unit pulse bag-type dust collector is generally above 99.6%, and the dust concentration of the outlet gas of the dust collector is within 30mg/m ³, which has a high classification efficiency for fine dust with sub-micron particle size;

The dedusting equipment can handle the minimum cubic meter of air per minute, and the large one can reach thousands of cubic meters, which is widely used in various small and medium-sized industrial flue gas dedusting;

DMC single-unit pulse bag-type dust collector is of integrated machine mode, with compact structure and small floor area;

The dust collector adopts the automatic control spray and blowing dust removal system to reduce the labor cost;

The pulse dust removal system of the equipment has high dust removal efficiency, which is especially suitable for the recycling of dust materials in the links of mixing, conveying, packaging and warehousing;

The filter bag of the dust collector can realize multiple film covering, effectively solving high temperature, adhesion, condensation and other problems.

Example: Dust Treatment in Aluminum Products Processing Workshop DMC Stand-alone Pulse Bag-type Dust Removal System

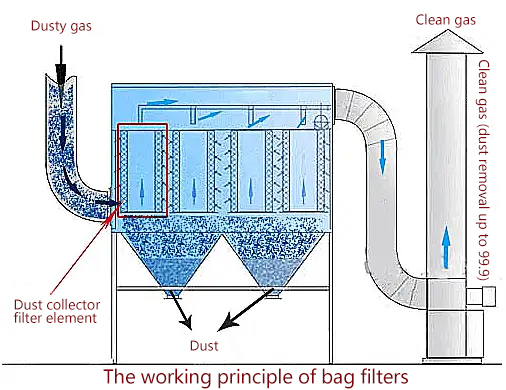

3、 Principle of single-machine bag dust collector

Under the adsorption of dust collector suction cover, the dust-containing gas enters the lower box of dust removal equipment from the air inlet (under normal settings), the dust is blocked by the filter bag, and the purified gas filtered by the filter bag is directly discharged by the fan suction. With the increase of the operating time of the dust collector, the dust accumulated on the filter bag is more and more, forming a new barrier layer, improving the filtration effect, but at the same time, the resistance of the filter bag is also increased, resulting in the gradual reduction of the treatment air volume. When the resistance value reaches the set range, the dust collector starts to realize automatic pulse dust removal without shutdown.

During dust removal of the dust collector, the pulse controller triggers each control valve in order to open the pulse valve. The compressed air in the air bag is ejected into the filter bag through each hole of the pulse valve to the blowing pipe in a short time, and the filter bag expands rapidly, so that most of the dust on the surface of the filter bag falls off, the filter bag is cleaned, and a small amount of dust is adsorbed on the surface of the filter bag to continue to help filtration. The dust cleaned by the filter bag falls into the ash hopper arranged under the dust collector and is discharged through the ash discharge valve. Thus, the dust accumulated on the filter bag is periodically cleaned, so that the dust gas is continuously purified, and the dust removal purification or dust collection function of the dust removal equipment is realized.

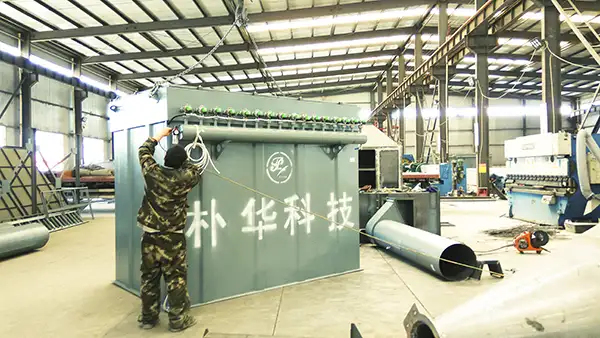

DMC single-unit bag-type dust collector equipment workshop production

Delivery of DMC single-unit bag dust collector to Hunan Province

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details