Dividing pulse bag-type dust collector

Industrial Dust Collectors

Dividing pulse bag-type dust collector

The compartment pulse bag filter is a new type of bag filter equipment developed by Puhua Technology based on the summary of various bag filters. It adopts a compartment dust removal structure and can be divided into two types according to actual needs: online pulse jet bag filter and offline pulse jet bag filter.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Brief Introduction to Divisional Pulse Bag-type Dust Collector

Sub-chamber (air box) pulse bag-type dust collector is a new type of bag-type dust collector developed by Parkway Technology on the basis of summarizing various bag-type dust collector. It adopts the structure of sub-compartment dust collector. According to the actual needs, it can be divided into online injection pulse bag-type dust collector and offline injection pulse bag-type dust collector. When the pulse bag-type dust collector is used for dust removal, the compressed air is directly ejected into the dust removal filter bag through the jet pipe hole at the upper part of the filter bag mouth. All the filter bags in a dust removal room are uniformly ejected, and the dust removal effect of the filter bag is good, so it is a popular pulse dust collector at present.

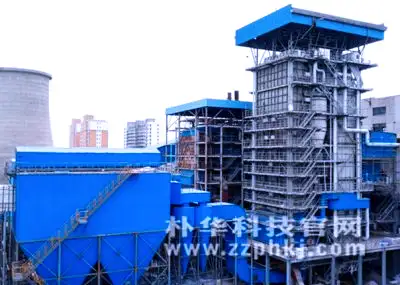

Delivery of high-efficiency pulse bag-type dust collector from plant area

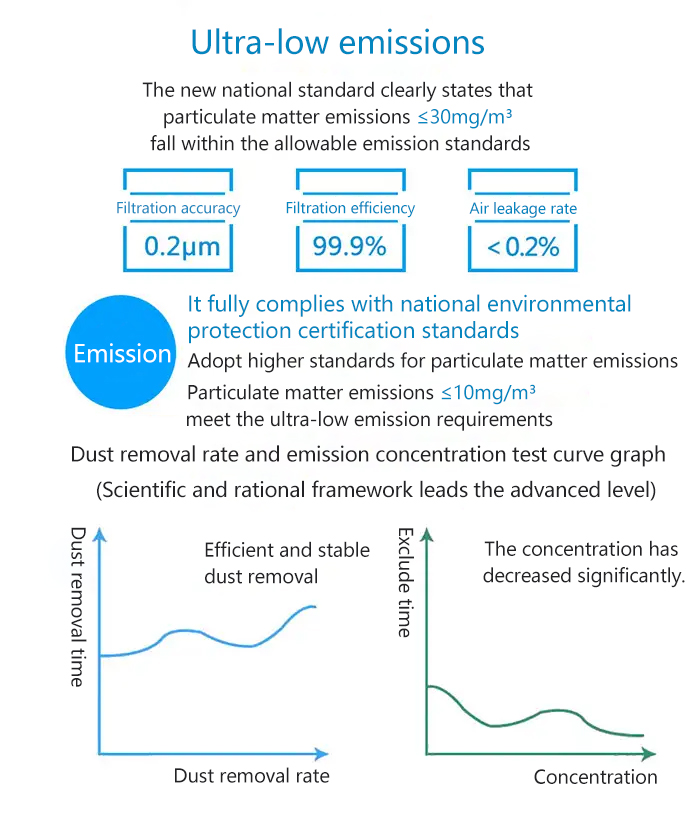

2、 Performance of chamber pulse bag-type dust collector

Low-pressure pulse jet technology, also known as low-pressure jet pulse dust collector, is adopted for the pulse bag-type dust collector, with high dust removal efficiency and low energy consumption;

The pulse bag-type dust collector adopts the stepped air-inlet and air-flow distribution technology and ash hopper diversion technology, which not only can make the airflow distribution uniform, but also can effectively reduce the equipment resistance and extend the service life of the filter bag;

The dust removal system of the dust collector adopts the large-capacity pulse jet blowing combination technology, which can realize the dust removal more effectively;

The dust collector adopts the imported pulse valve (pulse solenoid valve), and the service life of the vulnerable parts diaphragm exceeds 1 million times;

Generally, the pulse bag-type dust collector adopts the special filter material for industrial kiln, and the normal service life of the filter bag is more than 2 years.

3、 Principle of chamber pulse bag-type dust collector

When the chamber pulse bag-type dust collector is working, the dust-containing gas enters the dust hopper of the dust collector from the lower part of the dust collector box (large equipment has a special flue inlet and outlet air system). Due to the sudden expansion of the air flow sectional area and the decrease of the flow rate, a part of the coarse particles and dense particles in the dust-containing gas are settled by gravity and directly fall into the dust hopper of the dust collector; The particles with fine particle size and small density enter the filtering chamber distributed in the filter bag, and are attached to the filter bag surface and form a dust layer through the inertial, collision, screening, interception and electrostatic adsorption of the filter bag surface. The filtered clean gas is discharged from the exhaust pipe through the fan through the upper clean gas chamber.

The resistance value of the bag-type dust collector increases with the increase of the thickness of the dust layer on the surface of the filter bag. When the dust on the surface of the dust removal filter bag continuously increases and causes the resistance of the bag-type dust collector to rise to the set value, the time relay (or micro-differential pressure controller) outputs signals and the program controller starts to work one by one to open the pulse valves so that the compressed air sprays the filter bag through the nozzle to remove dust, so that the filter bag suddenly expands. Under the action of the reverse airflow, the dust attached to the surface of the filter bag quickly separates from the filter bag and falls into the ash hopper (or ash bin), and the dust is discharged from the ash discharge valve. When all filter bags of one dedusting room are blown and cleaned, the dedusting room returns to normal operation, and other dedusting rooms start to clean dust.

In order to achieve higher dust removal efficiency, it is important to retain a dust layer on the surface of some filter bags. Therefore, when designing the dust removal system, the chambered pulse bag-type dust collector produced by Parkway Technology only damages and removes a part of the dust layer from the filter material, instead of removing all the dust on the filter bag. The left dust layer will assist the filter bag to filter the new dust.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details