XLP cyclone dust collector

Industrial Dust Collectors

XLP cyclone dust collector

The Puhua Technology XLP cyclone dust collector is not limited by the concentration and temperature of the dust-laden gas, and has no special requirements for the physical properties of the dust. It can be lined with corundum, ceramics, etc. according to the customer's workshop and dust conditions, improving the wear and corrosion resistance of the dust collector.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to cyclone dust collector

Cyclone dust collector is a typical type of mechanical dust collector. It is a dust removal equipment that separates dust particles from the air flow by centrifugal force and inertia force, and it is also called cyclone separator. XLP cyclone dust collector is improved and designed based on the practice of C-type cyclone dust collector. It belongs to bypass cyclone dust collector and is a cyclone dust collector with a bypass channel outside the cyclone cylinder.

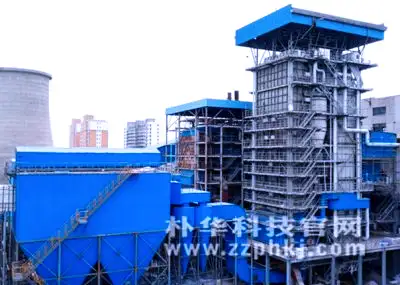

Img alt="CYCLONE EQUIPMENT IN FIELD INSTALLATION" src=“ https://www.zzphkj.com/uploads/allimg/200909/2-200Z9103052V2.webp On-site installation of cyclone dust collector

The cyclone dust collector allows a part of the gas containing more dust near the inner wall of the cyclone to enter the lower part of the cyclone through the bypass, so as to reduce the chance of dust escaping from the exhaust outlet, and has a high dust removal efficiency especially for the dust greater than 5 μ m.

XLP cyclone dust collector is commonly used to remove non-fibrous and cohesive dust with high density in industrial waste gas. It can effectively separate tobacco ash, talc powder, quartz powder, limestone powder, slag cement, cement raw meal, etc. It is characterized by simple structure, convenient operation, high temperature resistance, low resistance and high dust removal efficiency. It is applicable to gas purification of industrial departments such as mines, metallurgy, refractory materials, coal, chemical industry, building materials and electric power. With the improvement of environmental protection emission standard, it is mainly used for the pretreatment of dust gas in this field.

The XLP cyclone dust collector of Parkway Technology is not limited by the concentration and temperature of the dust-bearing gas, and has no special requirements for the physical properties of the dust. Corundum, ceramic and other linings can be added according to the customer's workshop and dust conditions to improve the abrasion resistance and corrosion resistance of the dust collector.

2、 Operating principle of cyclone dust collector

When the dust-containing gas cuts into the dust collector from the air inlet, the gas is divided into the upper and lower air flows while obtaining the rotational motion and presenting the double-vortex motion. The dust is strongly separated at the bottom of the exhaust, i.e. at the boundary of the double vortex. The fine and light dust particles are brought to the upper part by the upper vortex air flow, forming a strong rotating ash ring under the top cover to generate dust particle aggregation, and are led out from the upper opening of the special bypass separation chamber, and introduced into the lower part of the dust collector cylinder from the return air outlet on the outer wall of the dust collector to join with the internal air flow. The dust is separated and falls into the ash hopper. Driven by the lower vortex air flow, the other part of coarse and heavy dust particles are separated and sent into the ash hopper through the similar process of upper vortex air flow along the lower section of the dust collector.

3、 Performance characteristics of cyclone dust collector

XLP cyclone dust collector has small floor area and less manufacturing and installation investment;

The cyclone dust collector has large operation flexibility, stable performance and can adapt to various working conditions;

The bottom of the dust collector cone is provided with a reflective screen to prevent the secondary airflow from raising the separated dust again;

Cyclone dust collector with coating is added, the abrasion resistance is 20-30 times of ordinary carbon steel, the temperature resistance is more than 450 ℃, and the high-temperature exhaust gas can be directly treated;

XLP cyclone dust collector has no moving parts, no special auxiliary equipment, less pressure loss, less power consumption and lower operation and maintenance costs.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details