Air box pulse bag-type dust collector

Industrial Dust Collectors

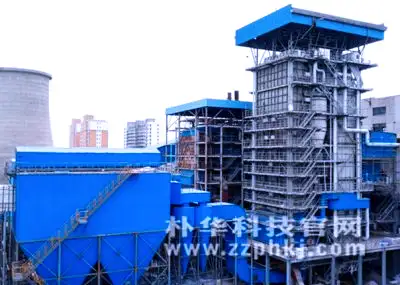

Air box pulse bag-type dust collector

The Zhengzhou Puhua Technology air box pulse bag filter is a large-scale pulse bag filter with sub-chambers and offline capabilities, which is more suitable for filtering and purifying dust gas in industries with high dust concentration, large dust volume, and strict environmental emission requirements.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to Airbox Pulse Bag Filter

The air-box pulse bag-type dust collector is a large pulse bag-type dust collector manufactured by Parkway Technology. The dust collector combines the advantages of various bag-type dust collector such as chambered reverse blowing bag-type dust collector and pulse jet bag-type dust collector. The large electromagnetic pulse valve is used to filter the dust and gas by chambered so as to realize dust removal by pulse jet. It has many advantages such as large air volume, strong dust removal capacity, good dust removal effect, low emission concentration and long service life.

The air-box pulse bag-type dust collector can not only purify the general dust-containing gas, but also handle the high concentration gas with the inlet concentration up to 1300mg/Nm ³. It becomes the classic finished powder recovery equipment matched with O-Sepa powder concentrator and vertical mill, and is widely used in the large powder processing industry.

Delivery of high-efficiency pulse bag-type dust collector from plant area

2、 Performance characteristics of air-box pulse bag-type dust collector

The air-box pulse bag-type dust collector manufactured by Parkway Technology is designed as an internal chamber structure, with large gas handling capacity and good dust removal effect;

The dust collector adopts pulse jet blowing mode, the solenoid valve is an imported diaphragm, the service life is long, and the equipment operates stably;

The dust collector adopts timing and fixed resistance dual selection ash removal mode, with small fluctuation of operating resistance, uniform ash fall, stable dust removal effect and long service life of equipment;

The dust remover is designed to remove dust off-line by rooms, with precise design. The dust removal efficiency can reach more than 99.9%, and the dust emission can be controlled below 20mg/Nm ³;

The dust collector adopts PLC automatic control, with simple operation management, stable performance and small maintenance workload in the later period.

Img alt="Performance characteristics of air-box pulse baghouse" src="/static/upload/image/2021028/16984660995515700. webp" border="0" vspace="0" style=""/>

3、 Operating principle of air-box pulse bag-type dust collector

When the dust-containing gas enters the dust collector from the air inlet flue, a part of coarse dust particles fall into the dust hopper due to inertia, collision, natural sedimentation and flue wall blocking. Most of the dust sinks after being filled with the flue with air flow, and enters from the bottom of each dust removal room after being evenly distributed by the air distribution system. Due to the blocking of dust removal filter materials, friction electrostatic adsorption between the dust and other effects, the dust is retained on the outer surface of the filter bag, and is gradually covered and overlapped to form a dust layer, further improving the filtration capacity of the filter bag for subsequent dust.

Under the guidance of the air flow of the induced draft fan, the dust gas is purified by the filter bag, enters the air purification chamber box from the inside of the filter bag, and is discharged into the atmosphere through the valve plate hole and air outlet to achieve the purpose of dust removal.

With the continuous filtration process, the dust layer on the surface of the filter bag is gradually thickened, and the filtration resistance of the dust removal equipment is increased. When the resistance reaches the preset value, the ash removal control system sends a signal for ash removal. At this time, the lifting cylinder is opened, the valve plate hole is closed, the entire dust removal chamber is isolated, and the pulse controller guides the electromagnetic pulse valve for soot blowing. When the dust removal is completed, the lifting cylinder retracts, the lifting valve opens again, and the dust removal room enters the filtration working state again. Each dedusting room is conducted in turn to realize independent filtration and ash removal.

The dedusting control system of pulse-box bag-type dust collector of Parkway Technology has two control modes: timing and fixed resistance, which can be flexibly selected according toactual production conditions.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details