Composite pulse dust collector

Industrial Dust Collectors

Composite pulse dust collector

The compound dust collector combines the respective advantages of the cyclone dust collector and the pulse bag dust collector, and performs graded treatment on dusty gas. With high treatment efficiency, the dust removal effect can reach 99.99%, making it widely used in dust removal in many precision workshops.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to composite pulse dust collector

Combined dust collector combines the working principles of cyclone dust collector and pulse bag-type dust collector, and uses the pre-dedusting function of cyclone dust collector to fully mix the dust-bearing air flow, pre-treat the dust particles and separate the coarse dust in advance. It not only effectively protects the dust removal equipment and reduces the wear of equipment parts, but also enables the pulse bag-type dust collector to give full play to its special features of precision filtration, achieve the dedusting and purification capacity, and achieve the dedusting effect of 99.99%.

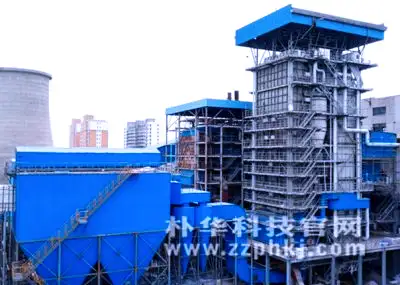

Img alt="Composite pulse dust collector is installed at the customer's plant" src=“ https://www.zzphkj.com/uploads/allimg/200907/2-200ZG60052A1.webp Composite pulse bag-type dust collector equipment is installed in the customer's plant

2、 Performance characteristics of composite pulse dust collector

Composite dust collector adopts combined structure, with reasonable matching, compact structure, small floor area and low overall energy consumption;

The composite dust collector is equipped with a famous brand pulse valve blowing device, with good dust removal effect, low equipment operation failure and long service life;

The composite dust collector also adopts automatic electrical control system with high degree of automation, and a variety of ash removal methods are selected by customers;

The purification efficiency of composite dust collector is high, and the purification efficiency of 0.5 micron fine dust is up to 99.99%.

3、 Operating principle of composite pulse dust collector

The dusty flue gas first enters the cyclone dust collector cylinder through the openings set on both sides. Affected by the cylinder wall, the gas rotates from top to bottom. Under the action of centrifugal force, the dust particles are thrown to the outer wall and sink to the bottom ash hopper and discharged by the ash discharge valve for collection. As the rotating downward airflow is gradually converged to the center due to the influence of the cone shape, the airflow center will form the reverse airflow from bottom to top, which is called internal swirl. Due to centrifugal action, the internal circulation often contains only small particles of dust.

The internal cyclone carries fine dust into the main body of the pulse bag-type dust collector. Due to the sudden increase of the sectional area, the airflow is dispersed and the speed is reduced, part of the dust automatically settles to the ash hopper at the bottom of the dust collector under the action of its own gravity, and the finer dust is absorbed and blocked on the surface of the filter bag under the action of negative pressure. With the accumulation of dust on the surface of the filter bag, a dust layer is gradually formed to block the later dust together with the filter bag, improving the filtration effect and increasing the resistance of the dust collector.

When the internal resistance of the dust collector reaches the set limit value, the injection controller controls the electromagnetic pulse valve and opens the injection and blowing dust removal system. The regulated high speed compressed gas vibrates and swells the filter bag, forcing most of the dust on the surface of the filter bag to fall off and fall into the ash hopper below to be discharged and collected through the ash discharge valve. The residual thin dust layer continues to assist the filter bag for filtration, so that the purpose of continuous and automatic dust removal of the dust collector is realized.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details