Divisional pulse filter cartridge dust collector

Industrial Dust Collectors

Divisional pulse filter cartridge dust collector

The compartment pulse filter cartridge dust collector designed by Zhengzhou Puhua Technology combines the advantages of compartment pulse bag filters in handling large air volumes, while also possessing the benefits of filter cartridge dust collectors, such as small footprint and high filtration accuracy. It is commonly used in various industries requiring high air volume and high-precision dust removal, such as ore processing, ultra-low flue gas emissions, and micro-powder material recovery.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Operating principle of chamber pulse filter cartridge dust collector

The chambered pulse filter cartridge dust collector evenly distributes the dust-containing gas to each dust removal room through the air duct. After the dust-containing gas enters the filter cartridge dust removal room, the air flow velocity slows down due to the sudden increase of the sectional area, and the fine dust is blocked on the surface of the filter cartridge with the air flow under the action of the exhaust fan. The clean gas enters the clean air chamber through the top of the filter cartridge and is discharged through the air duct.

When the ash layer on the surface of the filter cartridge is thickened gradually, the resistance of the dust collector increases continuously. When the resistance reaches the preset limit value, the pulse injection controller sends a command to open the electromagnetic pulse valve, and the compressed air in the air bag is ejected to the inside of the filter cartridge at a high speed. Meanwhile, under the action of the injection pipe, several times of the ambient air volume enters the filter cartridge and impinges on the filter cartridge from inside to outside, so that the dust on the outer surface of the filter cartridge is vibrated or blown into the dust collecting chamber below, and finally discharged by the discharge valve. Repeatedly, the filter cartridge dust collector can continuously and automatically remove dust and dust.

Through the continuous circulation of each filter cartridge dedusting chamber, the chamber pulse filter cartridge dust collector realizes the filtration and capture of gas to achieve the purpose of purification and dust particle recovery.

Inclined pulse filter cartridge dust collector

2、 Performance advantages of chamber pulse filter cartridge dust collector

The structure design and material selection of filter materials adopted by the pulse filter cartridge dust collector of the compartment are strict, which can meet the high environmental protection requirements of 5mg/Nm ³;

The chamber pulse filter cartridge dust collector adopts the chamber pulse dust removal technology to ensure the dust removal intensity and effect;

The chambered pulse filter cartridge dust collector has compact structure, small floor area, large treatment air volume and good use effect;

The dust collector is also equipped with automatic over-temperature alarm and emergency cooling control to ensure the safety of dust removal equipment;

The main body of dedusting equipment of the chambered pulse filter cartridge dust collector is designed and manufactured according to the service life of more than 15 years, and the average service life of the filter cartridge is also more than 18 months.

3、 Scope of application of chamber pulse filter cartridge dust collector

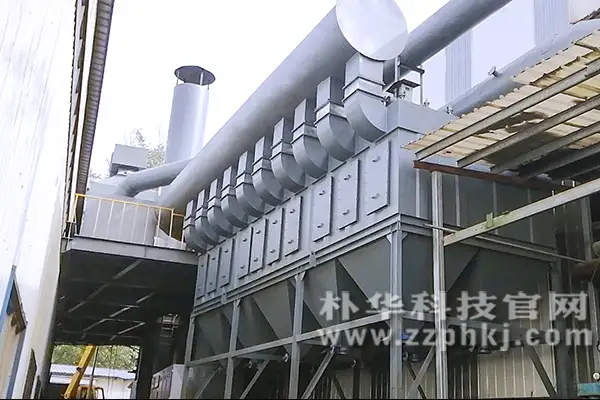

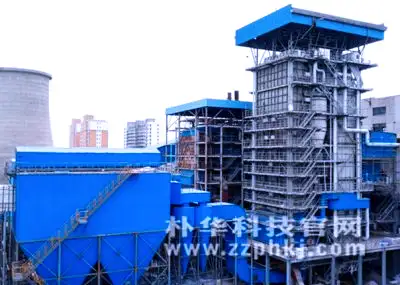

4、 Installation Case of Divisional Pulse Filter Cartridge Dust Collector

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details