Biomass boiler dust collector

Industrial Dust Collectors

Biomass boiler dust collector

The biomass boiler dust collector, manufactured by Puhua Technology, is a large high-temperature bag filter that excels in purifying high-temperature flue gas from biomass boilers. It is also suitable for the treatment of high-temperature dust and flue gas in any other industries.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to Biomass Boiler Dust Collector

Biomass boiler dust collector is a large high temperature bag dust collector produced by Zhengzhou Pihua Technology Co., Ltd. From design to manufacture, the operation conditions of bag dust collector under high temperature environment are fully considered, and special treatment is carried out in terms of high temperature resistance and corrosion resistance, so as to ensure stable operation of dust collector during high temperature flue gas purification.

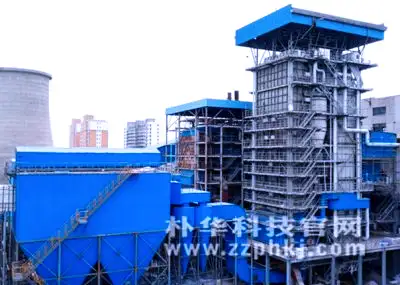

Img alt="Biomass boiler dust collector equipment installed at the customer's plant" src=“ https://www.zzphkj.com/uploads/allimg/200915/2-2009151A1061H.webp "/>

The biomass boiler dust collector equipment is installed in the customer's plant area

Glass fiber filter bag (temperature resistance 120 ℃ - 260 ℃, good comprehensive performance and medium price) is generally used for the biomass boiler dust collector. PPS (high temperature resistant material with excellent comprehensive performance), FMS (P84 fiber added on the basis of glass fiber, low running resistance) and other high temperature filter bags can be selected according to the customer's requirements. The cage of the dust collector is sprayed with organic silicon, with good heat resistance. The combination of high temperature resistant filter bag and high strength dust collector box can ensure that the dust removal equipment always maintains good filtration treatment effect during the flue gas purification process of the high temperature boiler.

2、 Performance characteristics of biomass boiler dust collector

The reinforced dust collector box is adopted by the biomass boiler dust collector manufactured by Parkway Technology, which is more stable when handling the high temperature flue gas with large air volume;

Glass fiber high temperature filter bag and organic silicon spraying high temperature cage, high cost performance;

The dust collector adopts pulse jet blowing for dust removal, the equipment operates stably and the dust removal efficiency is high;

The dust collector is equipped with PLC electric control system, with high automation degree and convenient management and operation;

The equipment can be flexibly improved according to different characteristics of flue gas in specific industry, with wide application range.

3、 Operating principle of biomass boiler dust collector

High-temperature flue gas passes through the cooling device (air cooling system designed and manufactured by our company), the temperature is controlled to the treatable range, and then enters the boiler dust collector after preliminary dust removal and purification by the pre-dust removal equipment (ceramic cyclone dust collector or gravity dust collector). The flue gas is uniformly distributed to each dedusting room through the air inlet flue, purified by the high temperature filter bag, and the clean gas is discharged from the clean gas room and the air outlet flue into the chimney; Dust particles are retained on the surface of the filter bag and accumulate more and more with time until the resistance of the dedusting chamber reaches the preset value, then the dedusting chamber starts to enter the dedusting mode, and other dedusting chambers continue to filter the flue gas.

For the dedusting room in the dedusting mode, the connection with the air outlet flue will be cut off first to form a closed circuit, which will be offline and no filtration will be performed. The electric control system will send the ash removal command, the pulse solenoid valve will release the high pressure gas to clean the filter bag, the dust vibration on the surface of the filter bag falls into the ash hopper below and is collected, the ash removal work is completed, the dust removal room enters the filtration mode again, and the dust removal room with the next resistance reaching the set value enters the ash removal mode. In this way, the dust collector keeps working all the time to realize continuous filtration and purification of high temperature flue gas, so as to ensure that the discharged air always meets the standard.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details