Coal-fired boiler dust collector

Industrial Dust Collectors

Coal-fired boiler dust collector

The dust collector for coal-fired boilers is a low-pressure offline pulse jet bag filter specifically designed for flue gas treatment of coal-fired boilers. It is equipped with high-temperature resistant filter bags (PPS, Metas, glass fiber, etc.) and enhanced with coatings for acid and alkali resistance, corrosion resistance, waterproofing, oil resistance, and anti-static properties. It can achieve stable dust removal effects given the complex chemical properties of flue gas from coal-fired boi

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to Coal-fired Boiler Dust Collector

High-temperature resistant filter bags (PPS, METAS P84、 FMS, glass fiber and other materials), special film covering (PTFE, flame retardant, waterproof, oil proof, anti-static, acid and alkali resistant, corrosion resistant, etc.) is added, which improves the applicability of high temperature flue gas generated by coal-fired boilers, and enables the dust removal equipment to operate stably and permanently at 120 ℃ - 300 ℃. It shows good dust removal effect in the flue gas dust removal of many industrial coal-fired boilers such as power plants, steel plants and cement plants. The use of desulfurization and denitration systems produced by Parkway Technology can realize clean emission of flue gas from coal-fired boilers.

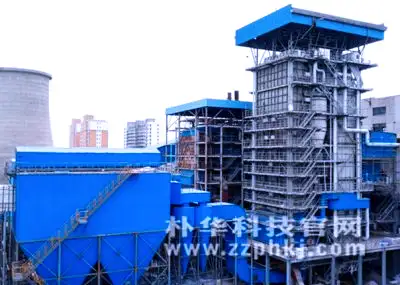

Coal-fired boiler dust collector equipment is installed in the customer's plant

Low-pressure pulse ash removal system is adopted for the dust collector of Puhua coal-fired boiler, with good system tightness, high ash removal efficiency and dust removal effect of over 99.5%, which can meet the requirements of environmental protection emission standard lower than 30mg/Nm ³. At present, the coal-fired boiler dust collector of Parkway Technology has been widely used in the high temperature flue gas purification fields such as smelting furnace flue gas treatment of iron and steel plants, flue gas dust removal and desulfurization of steam boilers of coal-fired power plants, waste incinerators and cement plant converters. Meanwhile, coal boiler dust collector is also widely used in chemical industry, metallurgy, casting, refractory processing and other industries producing high temperature dust and flue gas.

2、 Operating principle of coal boiler dust collector

In case of ultrahigh temperature environment, protective cooling measures such as air cooling and water cooling shall be taken before the coal boiler dust collector. When the flue gas temperature drops below 300 ℃, the dust collector can be directly used for filtration and purification.

High-temperature dust and flue gas enter the upper box of the dust collector from the special flue gas duct of the dust collector. Under the action of the wind shield and the air distribution system, the airflow velocity decreases and is uniformly distributed to each dust removal room for filtration and purification. During the flow process of flue gas, part of large particles of dust are separated out and fall into the ash hopper due to gravity and inertia force. For the flue gas entering the dust removal room, the dust is retained on the outer surface of the filter bag. The clean gas filtered by the filter bag enters the clean gas room through the filter bag mouth and is discharged from the dust collector through the air outlet. With the increasing dust on the surface of the filter bag, when the operating resistance of the dust collector reaches the set value, the control system sends the ash removal command and the ash removal system starts to work.

During dust removal of the dust collector, clean high pressure gas is released into the dust removal room, the filter bag is blown and expanded from top to bottom and then rapidly shrunk to recover, so that the dust attached to the surface of the filter bag is vibrated off, the dust collector is restored to the previous working state again, and the dust dropped into the ash hopper is finally collected and cleaned.

Under the control of the electric control system, the dust collector circulates above operations in turn under different conditions, so as to achieve long-term and stable filtration and purification of dust and flue gas, and make the discharged flue gas meet the national environmental protection requirements.

3、 Performance characteristics of coal-fired boiler dust collector

The body of the dust collector of the coal fired boiler of Parkway Technology is designed with full steel structure, and the flower plate adopts the cold stamping process, so the equipment has high compressive strength, small deformation at high temperature and good airtightness;

The dust remover adopts the off-line structure with large air volume, good dust removal effect, and the emission concentration can be lower than 30mg/Nm ³;

The dust collector adopts low-pressure pulse jet blowing dust removal mode, with high dust removal efficiency and good dust removal effect, which can effectively protect the dust removal filter bag;

Pak Hua Technology adopts high temperature resistant filter bag materials for coal-fired boiler dust collector, which has advantages in treating high temperature flue gas with complex composition;

Thermal insulation structure is added outside the dust collector, which can effectively prevent internal condensation water and condensation of filter bag caused by excessive temperature difference and ensure the service life of equipment;

The dust collector cooperates with PLC electric control system to realize automatic control, convenient operation and maintenance, and the dust removal efficiency is up to 99.5% or above.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details