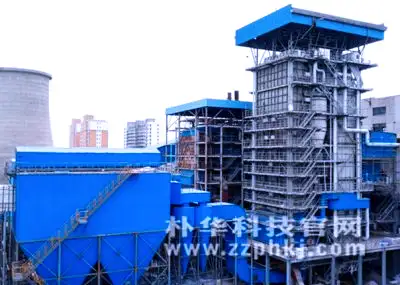

Crushing production line dust collector

Industrial Dust Collectors

Crushing production line dust collector

破碎生产线除尘器是一种专门针对各行业破碎生产线工作场所中的粉尘和污染物而设计的工业除尘设备,普遍用于矿山石料、采石、选矿、洗选煤等各行业的破碎除尘行业中。破碎生产线除尘器利用精良的过滤技术,将空气中的粉尘和有害物质进行捕捉,能够改善石料厂的工作环境,解决石料厂原始工艺中粉尘四溢的现象,符合环保要求。

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

I. Introduction to dust collector of crushing production line

The dust remover of crushing production line is an industrial dust removal equipment specially designed for dust and pollutants in the workplace of crushing production line of various industries, which is widely used in crushing and dust removal industries of various industries such as mine stone, quarrying, beneficiation and coal washing. Fine filtration technology is used for the dust collector of crushing production line to capture dust and harmful substances in the air, which can improve the working environment of the stone plant, solve the dust overflow phenomenon in the original process of the stone plant and meet the environmental protection requirements.

The dust collector of crushing production line mainly collects and treats the dust generated during crushing to prevent the dust from spreading to the surrounding environment. The dust remover of crushing production line can be designed one-to-one according to the workshop and outdoor site conditions of crushing production line to achieve the dust removal efficiency required by environmental protection and guarantee the health of workers.

Img sr="/static/upload/image/202412/172958253262. webp" alt="Crushing Line Dust Collector"/>

II. Performance of dust collector of crushing production line

1. High dust removal efficiency: modern crushing production line dust remover usually adopts excellent filtration technology, its dust removal efficiency can reach more than 99.9%, which can effectively trap tiny dust particles and ensure that the emission meets the standard.

2. Excellent environmental protection level: by effectively removing dust, the dust collector helps to reduce pollution to the surrounding environment and protect the ecological balance.

3. Stability of structure: the design of dust collector focuses on stability and durability. High-quality materials and manufacturing process are used to ensure long-term reliable operation of equipment.

4. Improving production efficiency: keep the equipment clean and avoid abrasion and blockage of mechanical equipment caused by dust, so as to improve production efficiency and service life of equipment.

5. Easy maintenance: convenience of maintenance is taken into consideration in the design of many dust removers, simple filter bag replacement operation, compact equipment structure and reduced maintenance cost.

6. Energy conservation and consumption reduction: some dust removers use energy conservation technology to reduce energy consumption and help enterprises save production costs.

7. Strong adaptability: the dust collector can adapt to different concentrations and natures of dust and different production scenarios, providing flexible solutions.

8. Automatic operation: the modern dust collector is equipped with an automatic dust removal system, which reduces manual intervention, improves the convenience of operation and stability of the system.

9. Guarantee of workers' health: Reduce the dust concentration in the workplace, reduce the risk of workers' occupational diseases and improve the working environment.

10. Compliance with environmental protection requirements: the design and performance of the dust collector meet or even exceed the national environmental protection standards, and help enterprises comply with increasingly strict environmental protection regulations.

Img sr="/static/upload/image/20241022/17295825147343. webp" alt="Crushing Line Dust Collector"/>

III. Operating principle of dust collector of crushing production line

The dust collector of crushing production line is mainly composed of box, ash hopper, filter bag and framework, air inlet system, injection device, ash unloading device, support, control system, air outlet and other parts.

The dust-containing gas first enters the dust collector through the air inlet, and the preliminary dust separation is carried out through the pre-treatment device (such as air inlet flow equalizing plate). The pre-treated gas enters the filter bag chamber, the dust particles are retained by the filter bag, and the clean gas enters the upper box through the filter bag. With the filtration process, the dust layer on the filter bag is gradually thickened, causing the resistance of the dust collector to rise. When the resistance reaches the preset value, the dust removal control system will start up, and the filter bag will be quickly blown back by the pulse injection system to expand the filter bag and shake off the dust. The dust after dust removal falls into the ash hopper and is discharged regularly through the ash unloading device. The purified gas is discharged into the atmosphere through the air outlet to complete the dust removal process.

The manufacturing process of dust collector of crushing production line includes material selection, cutting and processing, welding and polishing, spraying and anti-corrosion, assembly and commissioning, etc. Each link shall be operated in strict accordance with the design requirements to ensure that the quality and performance of the dust collector reach a better state.

Img sr="/static/upload/image/20241022/1729582559199780. webp" alt="Crushing Line Dust Collector"/>

IV. Application scope of dust collector in crushing production line

The dust remover of crushing production line is widely used in crushing and dust removal of mine stone, quarrying, beneficiation, coal washing and other industries, as well as in cone crusher, jaw crusher, impact crusher, impact crusher, vertical composite crusher and other processes.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details