Grinding table dust collector

Industrial Dust Collectors

Grinding table dust collector

The grinding table dust collector is an essential equipment for various processes such as welding, polishing, grinding, and plasma cutting. This product utilizes filtration technology, achieving a filtration efficiency of up to 99.9% for welding, cutting, and grinding fumes, while ensuring air flow.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to dust collector of grinding table

Polishing table dust collector, i.e. fan, motor, filter unit and workbench, is designed in one piece, with compact structure, smaller floor area and low noise after noise reduction treatment. Widely used in food processing, metallurgy, electricity, chemical industry, building materials, casting, machinery manufacturing and other industries of material recycling, dust collection recycling and air filtration.

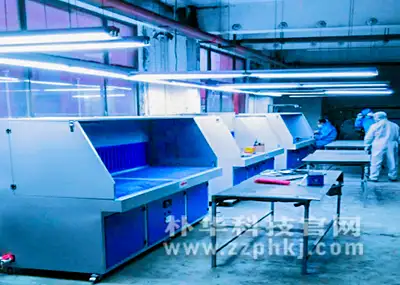

Img alt="On-site installation and commissioning of grinding table dust collector equipment" src=“ https://www.zzphkj.com/uploads/allimg/200915/2-2009151F312C6.webp "/>

On-site installation and commissioning of grinding table dust collector

2、 Operating principle of grinding table dust collector

The negative pressure generated by the smoke and dust through the fan enters the purifier through the side air outlet and the lower air outlet, and the air flows into the diversion channel. After the large particle dust collides with the deflector, the large particle dust falls into the ash collection drawer under the action of gravity, and the dust containing fine particles enters the filter chamber. The dusty gas passes through the filter element through the outer surface of the filter bag, and the dust is blocked on the surface by the filter element. When the blocked dust is continuously deposited on the filter element surface, the filter element is cleaned by the manual dust remover structure, or the dust on the filter cartridge can be cleaned by the pulse jet blowing, so that the dust particles deposited on the filter element are separated from the filter element surface and fall into the ash collection drawer under the action of vibration, so that the entire filter element surface is cleaned. The purified air is cleaned by the air. Discharged by fan.

3、 Performance characteristics of grinding table dust collector

The dust collector with workbench and dust collector is well designed, with air exhaust around, built-in dust removal system. The fan is soundproof, without pipe connection. The cleaned air can be discharged in the indoor circulation, greatly reducing the energy cost.

The new low-noise fan is adopted, with the same air suction volume and lower noise, which can guarantee the physical and mental health of the user.

Imported covered film dust removal filter cartridge is selected to effectively purify smoke and dust, and the filtration efficiency can reach 99.9% to protect the health of workers.

Compact structure, small floor area and simultaneous operation of two or more stations.

Select proper filter media according to the nature of dust generated under actual working conditions to adapt to the targeted treatment of dust with different natures.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

DMC single-unit pulse bag-type dust collector

View details

Dividing pulse bag-type dust collector

View details

Air box pulse bag-type dust collector

View details

Single pulse filter cartridge dust collector

View details

Divisional pulse filter cartridge dust collector

View details

Coal-fired boiler dust collector

View details

Biomass boiler dust collector

View details

Composite pulse dust collector

View details