Container domestic sewage treatment equipment

Wastewater Treatment Equipment

Container domestic sewage treatment equipment

The containerized domestic sewage treatment equipment is a series of sewage treatment devices designed by Puhua Technology based on the operational experience of domestic sewage treatment plants both domestically and internationally, combined with our own scientific research achievements and engineering practices. It utilizes carbon steel corrosion resistance as the main raw material, enabling domestic sewage and similar industrial organic wastewater to meet the emission standards required by us

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to container-type domestic sewage treatment equipment

The container-type domestic sewage treatment equipment of Parkway Science&Technology Co., Ltd. integrates the primary sedimentation tank, the first-stage contact oxidation tank, the secondary sedimentation tank and the sludge tank, and conducts air blast aeration in the first-stage contact oxidation tank to combine the contact oxidation method with the activated sludge method, so as to further improve the sewage treatment efficiency.

Example: Installation site of container-type sewage treatment equipment in shelter hospital

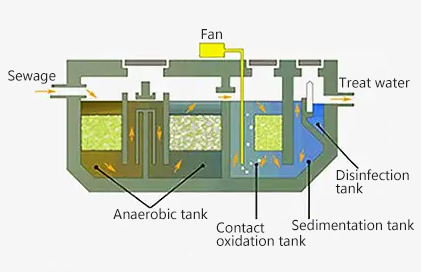

2、 Process flow of container-type domestic sewage treatment equipment

1、 Anaerobic tank

The pre-treatment before the sewage treatment will carry out anaerobic fermentation of the wastewater to improve the biodegradability of the sewage, so as to maximize the efficiency of sewage treatment and reduce consumption.

2、 Contact oxidation pond

The effluent from the anaerobic tank flows automatically to the contact oxidation tank for biochemical treatment, where most organics in the original sewage are degraded and purified. Aerobic bacteria take the filler as the carrier and organics in the sewage as food to decompose organics in the sewage into inorganic salts, so as to achieve the purification purpose.

3、 Sedimentation tank

The sewage will automatically flow into the sedimentation tank after being treated in the biological contact oxidation tank to remove the fallen biological membrane, part of organic matter and inorganic small particles. The adjustable outlet weir is set at the upper part of the sedimentation tank to regulate the outlet water level. The conical sedimentation area and sludge gas device are set at the lower part. The air source is provided by the fan. The sludge is transported to the sludge aerobic digestion tank by air stripping.

4、 Disinfection pool

Chlorine dioxide disinfection device is adopted. The dosing amount of disinfection tank and disinfection device can be changed according to the water volume, so as to achieve the purpose of adding more chemicals for more water and less chemicals for less water. Other devices can be prepared separately if necessary (for industrial sewage, the disinfection tank and disinfection device can not be used.)

3、 Scope of application of container-type domestic sewage treatment equipment

Sewage treatment in residential areas, enterprise dormitories and expressway service areas;

Hotel sewage treatment and enterprise domestic sewage treatment;

Coal mine domestic sewage treatment, villa sewage treatment and school sewage treatment;

New rural community sewage treatment and township sewage treatment;

Areas without urban pipe network, other similar sewage treatment projects.

4、 Treatment standard

Water Standard in Reuse of Urban Wastewater - Urban Miscellaneous Water Quality (GB/T18920-2002);

Discharge Standard for Pollutants from Municipal Sewage Treatment Plant (GB18918-2002);

Water Quality for Landscape Environment of Urban Wastewater Recycling (GB/T18921-2001).

5、 Equipment Selection Table

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Smart MBR sewage treatment equipment

View details

Container domestic sewage treatment equipment

View details

Integrated sewage treatment equipment

View details

Circulating water purification equipment

View details

Buried sewage treatment equipment

View details