Smart MBR sewage treatment equipment

Wastewater Treatment Equipment

Smart MBR sewage treatment equipment

The MBR wastewater treatment equipment utilizes a uniquely structured MBR flat membrane module placed in the aeration tank. After undergoing aerobic aeration and biological treatment, the wastewater is filtered through a membrane and pumped out. It employs membrane separation equipment to intercept activated sludge and macromolecular organic matter in the biochemical reaction tank, saving the need for a secondary sedimentation tank and greatly increasing the concentration of activated sludge. It

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to MBR Process

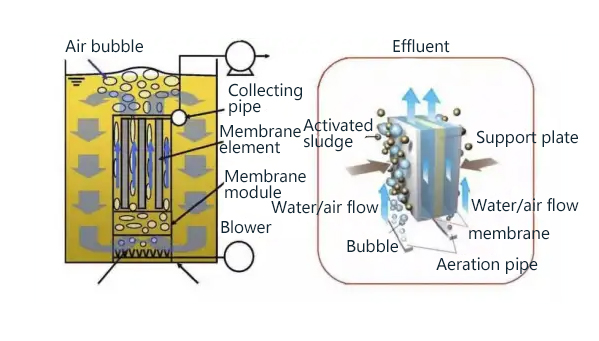

MBR, also known as Membrane Bio-Reactor, is a new sewage treatment process combining membrane separation technology with traditional activated sludge method. It is mainly composed of membrane separation module and bioreactor, as well as tank body, air blast and aeration system, pump, pipeline valve and instrument, etc.

MBR sewage treatment process adopts MBR plate membrane module to put it into the aeration tank. After aerobic aeration and biological treatment, the sewage is filtered by the filter membrane and pumped out. The membrane separation equipment is used to intercept the activated sludge and macromolecular organics in the biochemical reaction tank, save the secondary sedimentation tank, improve the concentration of activated sludge, control the hydraulic retention time (HRT) and sludge retention time (SRT) respectively, and continuously react and degrade the substances difficult to degrade in the reactor.

2、 Process flow

MBR integrated sewage treatment equipment mainly includes the following five units:

(1) Regulating tank (2) anoxic tank (3) MBR tank (4) clean water tank (5) equipment room

Strong>Regulating tank:It is mainly used to regulate the quantity and quality of sewage, and it can also be used as the emergency drainage storage site. The general volume is recommended to be 35% - 40% of the daily treatment capacity. It is suggested that the regulating tank should be built by the customer in a steel-concrete structure or included in the complete set of equipment.

Strong>anoxic tank:As the pre-treatment unit, the anoxic tank mainly plays the following roles: ① Provide a place for denitrification of wastewater, so as to fully convert the nitrate nitrogen generated during the nitrification process into nitrogen; ② Macromolecule organics are decomposed into micromolecules under the action of hydrolase to improve the biodegradability of sewage.

Strong>MBR tank:Membrane bioreactor (MBR) is the place where microorganism degrades organics. Membrane bioreactor can retain microorganism with long period and realize deep purification of sewage. Meanwhile, nitrifying bacteria can fully reproduce in the system and its nitrifying effect is obvious, providing possibility for nitrogen and phosphorus removal. Sludge return pump is set in the tank to return sludge to anoxic tank for denitrification, so as to ensure that the total nitrogen of sewage can reach the standard of reclaimed water reuse. Meanwhile, sludge discharge outlet is set on the pipe of sludge return pump to discharge sludge regularly (1-3 months) and ensure the sludge concentration in the membrane bioreactor. Membrane bioreactor can operate stably for a long time under the sludge concentration of 8000-15000ml/g.

Strong>Clean water tank:As the MBR water production storage tank, the clean water tank is also used as the membrane cleaning dosing tank. Meanwhile, it serves as the elevated water tank to prevent siphon phenomenon when the suction pump stops operating.

Strong>Equipment room:Equipment room is the place where mechanical and electrical equipment are placed. The equipment room is equipped with air blower, self-priming pump, PLC control cabinet and UV disinfection equipment.

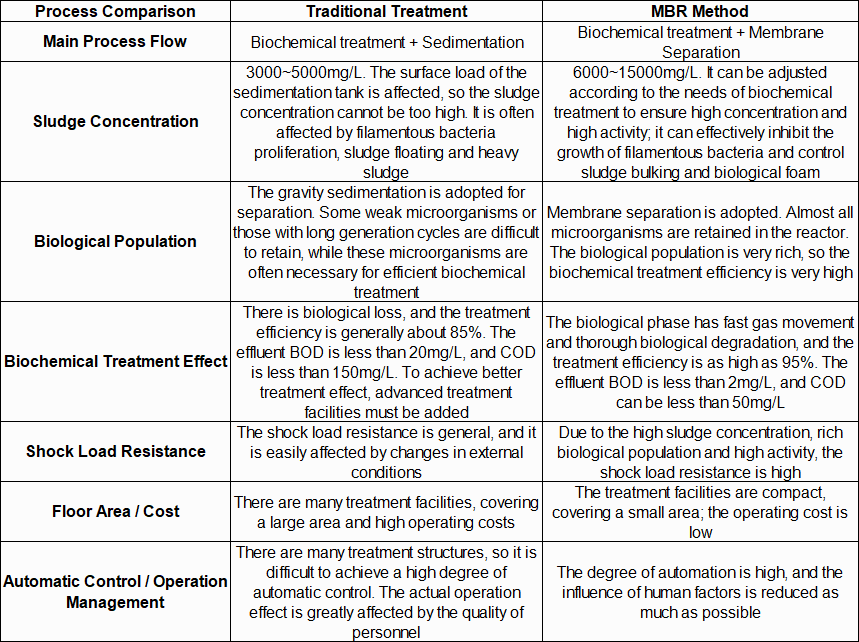

Sewage treatment process: comparison of biochemical treatment+sedimentation and biochemical treatment+MBR

3、 MBR membrane module

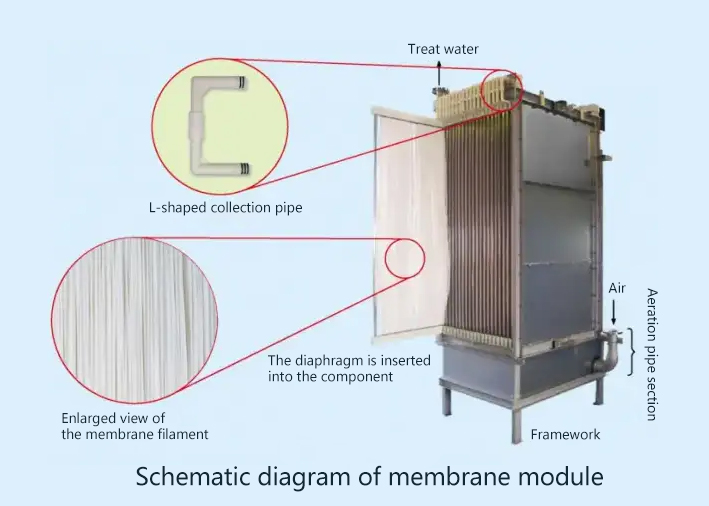

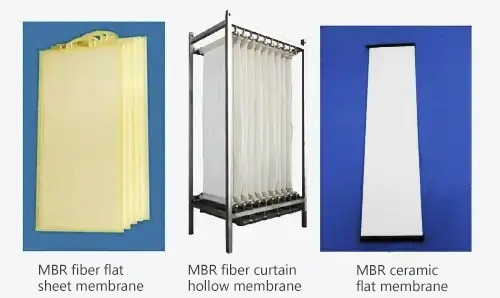

MBR membrane modules are divided into two categories: hollow fiber membrane and flat membrane modules. The common flat membrane module is a frame welded by 304 stainless steel. Insert the membrane one by one for fixation, and install the aeration pipe fittings and water collecting pipe fittings. Hollow fiber membrane module has low cost, but its maintenance and operation depend on professional team. Large municipal projects above 10000t/d are mostly used, and the cost of flat membrane module is high. However, it is simple in operation and maintenance, convenient for automatic control, and more suitable for small sewage treatment/reclaimed water reuse projects with a scale of 10-5000t/d.

4、 MBR membrane

Hollow fiber membrane and flat membrane are called "organic membrane" together, and the main material is PVDF (Polyvinylidene fluoride), which is the main material of all membranes on the market. Ceramic membrane is new in recent years and is called "flat membrane" together with organic flat membrane. Ceramic membrane has excellent chemical stability, acid resistance, alkali resistance, organic solvent resistance, high temperature resistance, narrow pore size distribution and high separation efficiency.

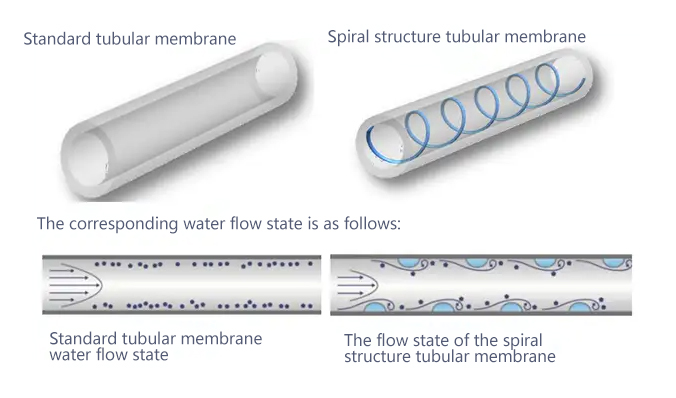

As a form of membrane element, the organic tubular membrane is applicable to membrane separation technologies such as ultrafiltration, microfiltration and even nanofiltration. Its advantages are wide flow passage, turbulent flow of feed liquid in the tube and low requirements for pretreatment accuracy of feed liquid. Tubular membrane is easy to clean and can be mechanically and physically scrubbed in addition to chemical reagent cleaning.

5、 Performance characteristics

Stable quality of effluent;

Small output of residual sludge;

Small floor area, not limited by setting site;

It can remove ammonia nitrogen and hardly degradable organics;

Easy operation management and automatic control;

Easily transformed from traditional process.

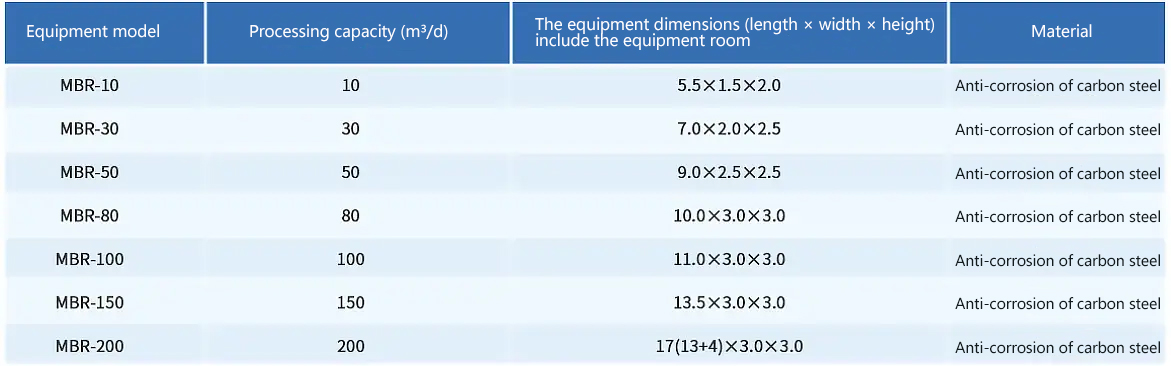

6、 Equipment Selection Table

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Smart MBR sewage treatment equipment

View details

Container domestic sewage treatment equipment

View details

Integrated sewage treatment equipment

View details

Circulating water purification equipment

View details

Buried sewage treatment equipment

View details