Catering wastewater treatment equipment

Wastewater Treatment Equipment

Catering wastewater treatment equipment

The catering wastewater treatment equipment is a new type of equipment independently innovated by Puhua Technology. This equipment innovates the oil-water separation process design, adopts a more economical and reasonable structural design, with a more reasonable and efficient hydraulic flow, better oil-water separation effect, and more convenient operation; it adopts a fully automatic operation system design, making management and maintenance more convenient. The effluent quality meets the envi

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to foodservice wastewater treatment equipment

Catering wastewater treatment equipment is a new kind of catering wastewater treatment equipment independently innovated by Parkway Technology. The equipment innovates the oil-water separation treatment process design, adopts more economical and reasonable structure design, the hydraulic process is more reasonable and efficient, the oil-water separation effect is better, and the operation is more convenient; Fully automatic operation system design, more convenient management and maintenance. It has such functions as complete automatic debris separation, convenient sludge separation and collection, automatic oil separation and collection, automatic sewage lifting and discharge, etc. The effluent quality meets the environmental protection requirements CJ343-2010 Quality Standard for Sewage Discharged into Urban Sewer.

Loading and delivery of catering wastewater treatment equipment

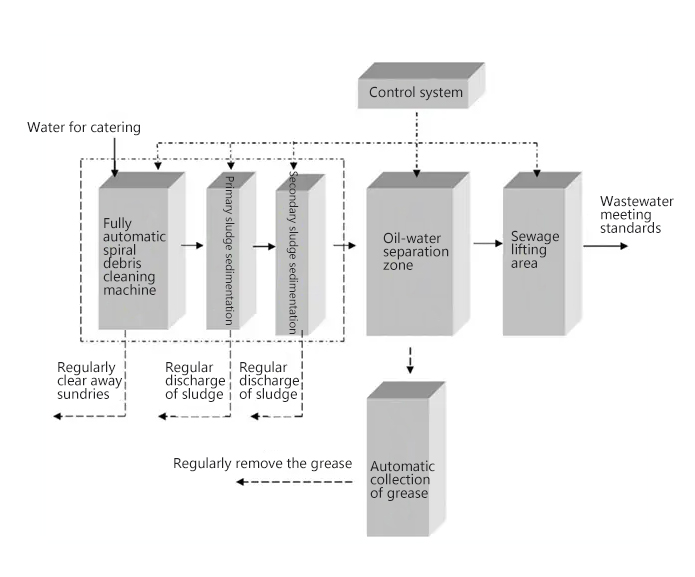

2、 Process flow and principle of catering wastewater treatment equipment

1. When the sewage enters the equipment, the debris separator will automatically intercept large particles (over 10mm in diameter) of solid impurities (large pieces of food, washing balls, rags, other kitchen wastes, etc.), and automatically operate to discharge to the debris collection bucket, so that the debris can be completely separated.

2. Oily waste water and fine particle solid impurities with diameter less than 10mm flow into the sludge collection and sludge discharge device, and oil absorption and sludge discharge are carried out through the special oil absorption and sludge discharge downpipe, so as to realize primary sludge collection and sludge discharge, and the sludge is discharged to the debris bucket regularly. It enters into the secondary sludge collection and discharge area through the oil suction and sludge discharge downpipe, and is deposited by the specially arranged sludge deposition device and discharged to the debris bucket regularly. At this point, the sludge is completely separated.

3. The oily wastewater entering the oil-water separation system is treated by the professional oil-water separation process flow, and the retention time and flow rate are controlled to ensure the automatic separation of oil and water in the laminar flow process. The separated grease is quickly collected into the oil drainage device through the conical top. The clean sewage after oil-water separation flows into the sewage lifting box automatically. So far, oil-water separation is realized. Two-stage oil-water separation device can effectively remove grease, and the grease removal rate is more than 99%. The grease collected in the oil drainage device is automatically collected and discharged through the special automatic oil drainage device. The daily only needs to replace the debris barrel and oil collection barrel, and the maintenance operation is simple.

4. When the sewage in the sewage lifting tank reaches the set liquid level, the water pump will start automatically to lift and discharge the sewage. When the normal liquid level control fails, the over-limit water level is set to start the pump forcedly and the audible and visual alarm is given. In order to ensure the safe and clean use of the equipment, the overflow pipe is specially set. Two pumps are provided for alternate operation and standby for each other to ensure drainage safety. A heating device is provided to ensure the oil-water separation effect and the solidification of grease are difficult to discharge.

3、 Dining wastewater treatment equipment advantages

Strong>Environmental protection:Advanced oil-water separation process, safe operation without hidden dangers, fully meeting and superior to environmental protection discharge requirements;

Strong>No odor pollution:The water tank, oil barrel and debris barrel are all designed with a fully sealed movable top cover, with an external only air vent, so that the odor does not overflow and has no impact on the surrounding environment;

Strong>No clearing:Debris, rice and other sludge, grease, etc. are stored and discharged in a professional designed area in an orderly manner, without manual clearing;

Strong>Safety:Multi-operational safety guarantee design, fully automatic operation and automatic fault detection to ensure the drainage safety of underground space;

4、 Scope of application of foodservice wastewater treatment equipment

Comprehensive emission treatment for catering of various commercial real estate and scientific and technological real estate; Dining wastewater treatment of enterprise and public institution canteen; Treatment, improvement and discharge of catering wastewater in various supermarkets, hotels and other catering places.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Smart MBR sewage treatment equipment

View details

Container domestic sewage treatment equipment

View details

Integrated sewage treatment equipment

View details

Circulating water purification equipment

View details

Buried sewage treatment equipment

View details