Limestone-gypsum desulfurization process

Desulfurization & Denitrification Systems

Limestone-gypsum desulfurization process

Puhua Technology's limestone-gypsum desulfurization process boasts sophisticated technology, extensive practical experience, low equipment operating costs, and high utilization rate of desulfurizing agents. It has been applied in multiple coal-fired boiler desulfurization projects, demonstrating significant desulfurization effects and stable equipment operation.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to Limestone-Gypsum Desulfurization

Limestone/limestone-gypsum desulfurization process adopts calcium base (limestone, quicklime, etc.) as desulfurization absorbent to have chemical reaction with sulfur-bearing flue gas in desulfurization tower and finally remove sulfur dioxide in flue gas. This process has a long history of development, perfect technology and stable desulfurization effect. Compared with various desulfurization technologies, it has obvious comprehensive advantages and is widely used by large units at home and abroad.

Limestone/lime-gypsum desulfurization process is applicable to a wide range of coals. It can be used for flue gas desulfurization, no matter high sulfur coal with sulfur content more than 3% or low sulfur coal with sulfur content less than 1%. This process has high desulfurization efficiency (when Ca/S=1.03, the desulfurization efficiency is greater than 95%), high absorbent utilization rate (can be greater than 90%), high equipment operation rate (can reach more than 90%), and abundant desulfurizer sources and low price. It is a commonly used desulfurization process in coal-fired flue gas treatment and a relatively perfect flue gas desulfurization process at present.

2、 Operating principle of limestone-gypsum desulfurization

Mix and mix powdered limestone with water to make desulfurization absorbent slurry (when quicklime is used as absorbent, add water to make desulfurization absorbent slurry after lime powder is digested). The desulfurizer enters the desulfurization tower under the guidance of pump set and is treated into mist slurry by atomizer at each layer.

The flue gas from the boiler or kiln enters the desulfurization tower under the action of induced draft fan after dedusting. The chemical reaction takes place in the reverse contact with the circulating slurry in the desulfurization tower, and the sulfur dioxide in the flue gas is absorbed. The slurry after absorbing sulfur dioxide enters the circulating oxidation zone, in which calcium sulfite is oxidized into gypsum crystal by blown air. At the same time, the absorbent preparation system supplies fresh limestone slurry to the absorption and oxidation system to supplement the consumed limestone, so as to keep a certain pH value of the absorption slurry. When the reaction product slurry reaches a certain density, it will be discharged to the desulfurization by-product system, and the gypsum will be formed after dehydration. The sulfur-containing flue gas will be purified in this process.

3、 Limestone-gypsum desulfurization process flow

Desulfurization process:

CaCO3+SO2+1/2H2O → CaSO3.1/2H2O+CO2

Ca (OH) 2+SO2 → CaSO3.1/2H2O+1/2H2O

CaSO3.1/2H2O+SO2+1/2H2O → Ca (HSO3) 2

Oxidation process:

CaSO3.1/2H2O+O2+3H2O → 2CaSO4.2H2O

Ca (HSO3) 2+O2+2H2O → CaSO4.2H2O+H2SO4

4、 Limestone-gypsum desulfurization advantages

The desulfurization rate of limestone/lime-gypsum desulfurization process is up to over 95%, with partial dust removal function;

The desulfurization process has perfect technology, long service life of equipment and is widely used in desulfurization of large units;

Limestone/lime-gypsum desulfurization process is applicable to desulfurization of flue gas of any coal with sulfur content, with wide application range;

China has rich limestone/lime resources, low price and low overall desulfurization process operation cost;

The by-product of limestone/lime-gypsum desulfurization process is dihydrate gypsum, which is widely used in building materials and cement industry for recycling.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

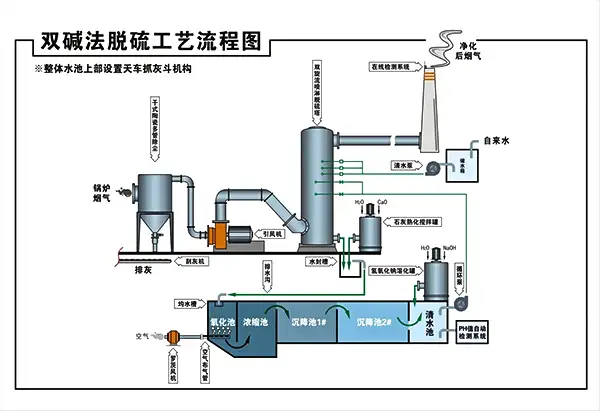

Dual-alkali desulfurization process

View details

Limestone-gypsum desulfurization process

View details

Desulfurization tower

View details

SCR denitration process

View details