SNCR denitration process

Desulfurization & Denitrification Systems

SNCR denitration process

The SNCR denitrification system designed by Puhua Technology adopts modular management and scientifically and reasonably distributes the positions of spray guns to achieve optimal denitrification effects. The entire equipment is compact in structure and occupies a small area, significantly reducing both investment and operational costs.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to SNCR denitration

SNCR (Selective Non-Catalytic Reduction) denitration technology is to inject reducing agent into the "temperature window"suitable for denitration reaction without using catalyst, so as to return nitrogen oxide in flue gas to harmless nitrogen and water. This technology is commonly used for flue gas denitration of coal-fired boilers. Generally, liquid ammonia, urea or hydrogen ammonia are injected into the boiler as reducing agent, and directly injected into the furnace at a temperature of 850-1250 ℃ to rapidly decompose into NH3 or amino substances, react with nitrogen oxide (NOx) in the flue gas to generate nitrogen, carbon dioxide and water. The generation of nitrogen oxide shall be avoided as far as possible during combustion in the boiler, so as to achieve the purpose of flue gas denitration of the boiler.

Example: SNCR denitration of Sanmenxia Aluminum Plant

In order to improve the denitration effect, the SNCR denitration system designed by Parkway Technology adopts modular management, including metering mixing module, pump delivery module, injection module, control module, etc., and scientifically and reasonably distributes the position of the spray gun in full combination with boiler combustion mode, flue gas recirculation (if used), excess air in the furnace, initial or baseline NOx concentration, temperature distribution of flue gas in the furnace, flow velocity distribution of flue gas in the furnace and other relevant factors to achieve effective denitration effect. The whole set of equipment is compact in structure, small in floor area, easy for installation, operation and maintenance, greatly reducing investment and operation cost.

Location of spray gun inside the furnace (selection of SNCR denitration injection point and denitration efficiency)

2、 SNCR denitration performance characteristics

For different furnaces, the denitration system of Parkway Science&Technology Co., Ltd. selects proper spray gun to ensure the denitration efficiency of SNCR system;

The Company shall select proper reducing agent according to the characteristics of specific boiler to help achieve better efficiency, lower reducing agent consumption and reduce the impact on boiler efficiency and operation;

When designing the SNCR system, the Company shall take into account the operation characteristics of the boiler itself to ensure the high efficiency denitration and the thermal efficiency of the boiler;

SNCR system designed by Parkway Technology adopts modular equipment, which is convenient for installation, simple for operation and maintenance, and good in dust prevention;

All modules have been subject to performance test before delivery, so as to ensure stable and durable operation of the equipment after installation.

Img alt="Case: Jinmailang Drink SNCR Denitration System" SCC=“ https://www.zzphkj.com/uploads/200714/2-200G4100526400.webp "/>

Case: Jin Mailang Drink SNCR Denitration System

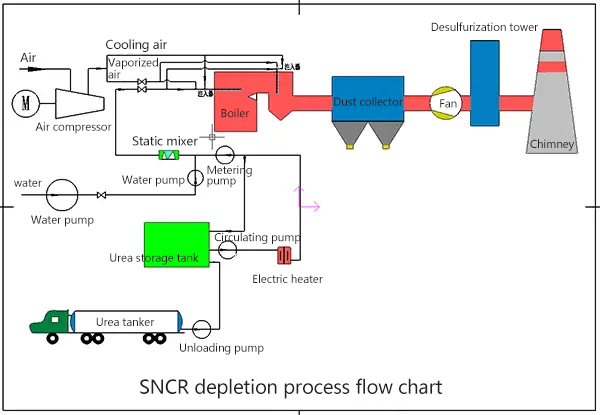

3、 SNCR denitration process flow

When NH3 is used as reducing agent:

NH3+4NO+O2 → 4N2+6H2O

NH3+2NO+2O2→3N2+6H2O

NH3+6NO2→7N2+12H2O

When urea is used as reducing agent:

NH2) 2CO→2NH2+CO

NH2+NO→N2+H2O

CO+NO→N2+CO2

4、 Working principle of SNCR denitration

Diluted liquid ammonia or urea solution is sent to the storage tank from the preparation module by the delivery pump set, and then lifted to the metering and distribution module by the submerged pump in the tank. All the mixed liquid is divided into equal parts corresponding to each spray gun in this module, and is ejected into different positions of the furnace at high speed. It quickly gasifies into ammonia or amino substances in a suitable temperature range, reacts with the nitrogen oxide in the furnace at high temperature, consumes the nitrogen oxide therein, generates nitrogen, carbon dioxide and water, and achieves the treatment of nitrogen oxide during combustion in the furnace, so as to achieve the purpose of flue gas denitration.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

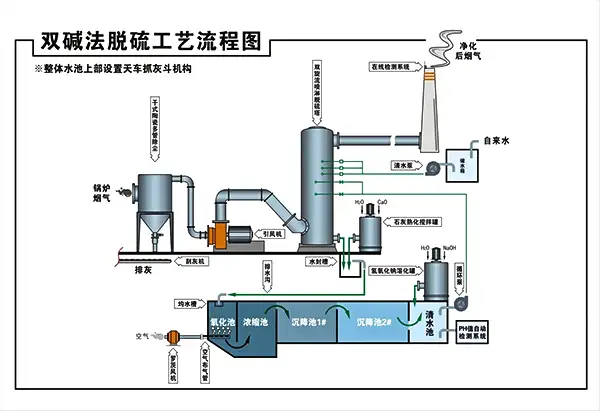

Dual-alkali desulfurization process

View details

Limestone-gypsum desulfurization process

View details

Desulfurization tower

View details

SCR denitration process

View details