SCR denitration process

Desulfurization & Denitrification Systems

SCR denitration process

The SCR denitrification system from Puhua Technology utilizes urea as the reducing agent, featuring refined technology, stable operation, and low operating costs. When combined with the desulfurization and dust removal processes and equipment developed by the company in flue gas denitrification for coal-fired boilers in power plants, the overall purification effect of the flue gas is excellent, and the effectiveness of its use is widely recognized by customers.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to SCR denitration

SCR (Selective Catalytic Reduction) denitration process adopts liquid ammonia or urea as reducing agent, selectively reacts with nitrogen oxide in flue gas and generates non-toxic and non-polluting nitrogen and water, so as to realize denitration of industrial flue gas.

SCR denitration process is the elimination technology after the generation of nitrogen oxide (NOx), and SNCR denitration process is one of the two major nitrogen oxide control technologies in the world. SCR desulfurization process has low reaction temperature (300-450 ℃), denitration efficiency ≥ 80%, ammonia escape rate ≤ 3ppm, and SO2/SO3conversion rate ≤ 1%. It is a flue gas denitration technology widely used and technically perfect in power plants at home and abroad.

2、 Operating principle of SCR denitration

The flue gas containing nitrogen oxide (NOx) enters the denitration reactor through the economizer. Ammonia gas and diluted air or flue gas are mixed. Under the action of catalyst, ammonia or urea solution and nitrogen oxide have reduction reaction to generate harmless nitrogen and water. At the later stage, the mole ratio of NH3/NOX in the reactor is maintained by adding or replacing new catalyst in the reactor, so as to continuously achieve the required denitration effect.

3、 SCR denitration process flow

Ammonia SCR denitration process:

NO+NO2+2NH3 → 2N2+3H2O

NO+4NH3+O2→4N2+6H2O

NO2+4NH3+O2→3N2+6H2O

Urea SCR denitration process:

NH2CONH2+H2O→2NH3+CO2

NO+4NH3+O2→3N2+6H2O

NO+4NH3→5N2+6H2O

4、 SCR denitration advantages

SCR denitration technology has fast denitration speed, high denitration rate and low ammonia escape;

SCR denitration technology catalyst reaction temperature is low, easy to handle large amount of flue gas, strong processing capacity;

Pihua Technology has designed the control system, which can effectively ensure the stable operation of SCR denitration system.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

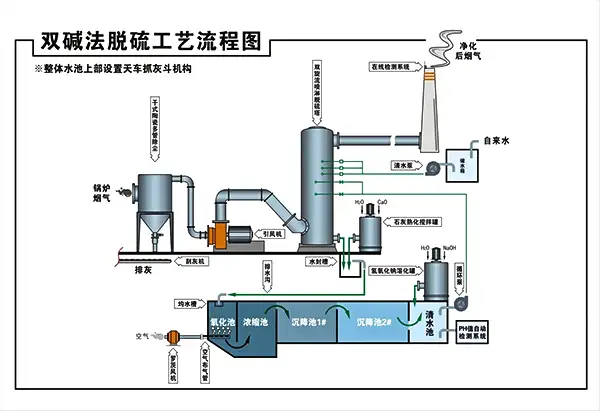

Dual-alkali desulfurization process

View details

Limestone-gypsum desulfurization process

View details

Desulfurization tower

View details

SCR denitration process

View details