Dual-alkali desulfurization process

Desulfurization & Denitrification Systems

Dual-alkali desulfurization process

Puhua Technology's dual-alkali desulfurization technology is well-established. It employs methods such as soda ash startup, sodium-calcium absorption of SO2, and lime regeneration to effectively purify sulfur-containing flue gas. The desulfurization efficiency is over 90%, making it widely applicable.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

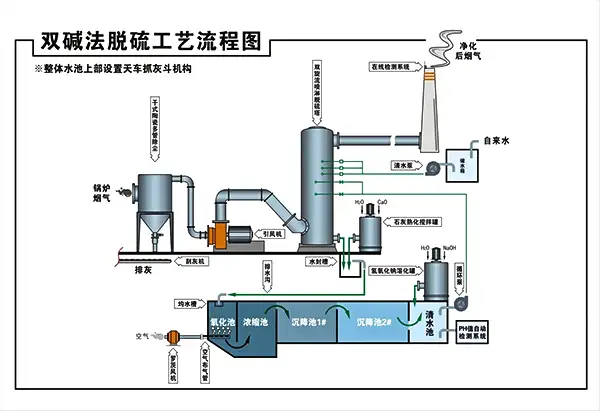

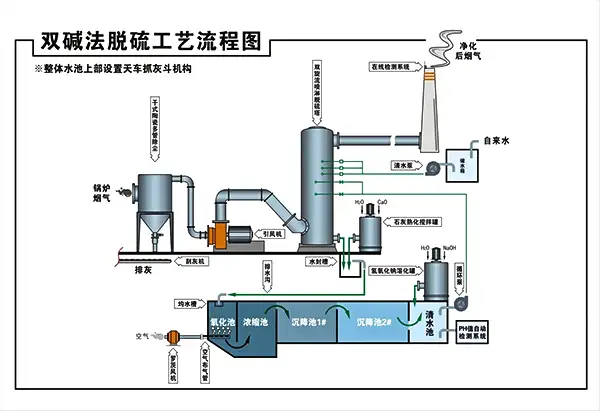

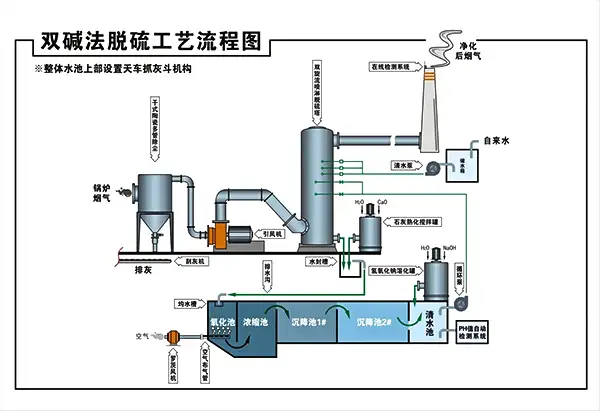

1、 Introduction to double-alkali desulfurization process

Dual-alkali desulfurization technology of Parkway Technology adopts sodium based desulfurizer for desulfurization. NaOH solution is sent into the desulfurizer for atomization and fully reacts with flue gas to remove SO2 in the flue gas. The desulfurized product is reduced to NaOH by Ca (OH) 2 through the desulfurizer regeneration tank and can be recycled again. Due to strong alkalinity of sodium based desulfurizer, not only the desulfurization effect is good, but also the solubility of reaction product is large after absorbing SO2, so the supersaturated crystal will not be generated, which can effectively avoid the scaling in the column.

Example: Double-alkali desulfurization transformation of Hebi Brickyard

2、 Working principle of double-alkali desulfurization

The sulfur-bearing flue gas is blown into the spray desulfurization tower by the induced draft fan under positive pressure after dust removal. Atomization system is set in the spray tower, and the space in this section is filled with atomized droplets with particle size of 100~300 μ m sprayed by atomizer. SO2 in the flue gas reacts with absorbed alkali again to remove more than 90% sulfur dioxide.

The reasonable selection and scientific arrangement of the spray system of Parkview Technology make the atomization zone form an atomization zone with no dead corner, less overlap and uniform distribution of atomized liquid. The flue gas passes through the atomization zone for a long time, and the SO2 in the flue gas has sufficient opportunities to contact with the desulfurization liquid and constantly collide with the fog drops. The SO2 reacts with the absorption liquid to be removed. At the same time, the residual dust is carried with "water drops" and sinks due to the increase of mass.

The desulfurized liquid falls into the bottom of the desulfurizer, and is regularly discharged into the collection system set behind the desulfurizer. After a certain amount of alkali liquor is properly supplemented, it is sent to the spray and liquid preparation system by the circulating pump for reuse. The desulfurizer is always in the circulating state. Desulfurization slurry after multiple cycles is discharged into the post-treatment system. Due to the particularity of the design, when the desulfurized flue gas passes through the tower top demister, the droplets in the flue gas are separated to achieve the effect of dust removal and mist removal at the same time, and the clean flue gas is finally discharged according to the standard.

3、 Double-alkali desulfurization process flow

Desulfurization process:

1) Preparation and supplement of absorbent;

2) Spray of absorbent slurry;

3) The fog drops in the tower are mixed with the flue gas;

4) Regeneration pond slurry reducing sodium base alkali;

5) Gypsum Dewatering Treatment.

Chemical reaction:

1) Desulfurization reaction:

Na2CO3+SO2 → Na2SO3+CO2

NaOH+SO2 → Na2SO3+H2O

Na2SO3+SO2+H2O → NaHSO3

2) Reduction reaction:

Ca (OH) 2+Na2SO3 → 2NaOH+CaSO3

Ca (OH) 2+2NaHSO3 → Na2SO3+CaSO3.1/2H2O+3/2H2O

3) Oxidation reaction:

CaSO3+1/2O2 → CaSO4

CaSO3.1/2H2O+1/2O2 → CaSO4+1/2H2O

4、 Dual-alkali desulfurization advantages

Sodium alkali and lime are used as desulfurizers in double-alkali desulfurization process of Parkway Technology, with fast reaction speed and desulfurization efficiency above 90%;

This process has a small liquid-gas ratio, which facilitates the integration of desulfurization and dust removal;

Common desulfurizer materials, abundant resources and low investment cost;

Desulfurizer is recycled and the operation cost is low, which is applicable to desulfurization transformation of small and medium-sized boilers.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Dual-alkali desulfurization process

View details

Limestone-gypsum desulfurization process

View details

Desulfurization tower

View details

SCR denitration process

View details