Desulfurization tower

Desulfurization & Denitrification Systems

Desulfurization tower

Puhua Technology boasts a comprehensive desulfurization technology. Its spray desulfurization towers are crafted from three distinct materials, catering to the needs of various industries. Depending on the sulfur content of the flue gas, a multi-layer spray tower structure can be employed, finding widespread application in both power plants and the non-ferrous metal industry.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to desulfurization tower

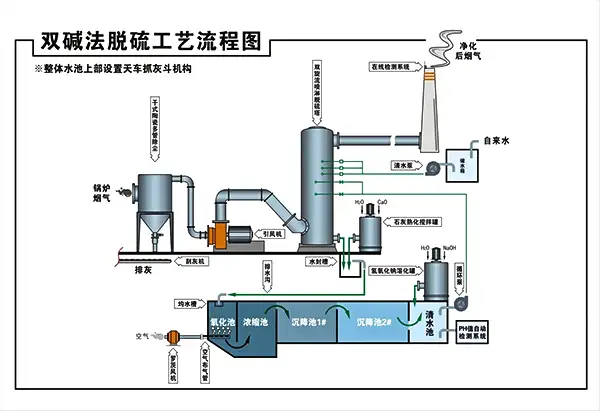

The coal-fired flue gas desulfurization equipment researched and developed by Parkway Technology is spray desulfurization tower, and the desulfurization process is limestone/lime-gypsum desulfurization and double-alkali desulfurization, which can be flexibly selected according to the actual situation of the customer. Among them, limestone/lime-gypsum desulfurization process technology is perfect and widely used in large desulfurization projects at home and abroad; However, the double-alkali desulfurization process has high desulfurization efficiency and low investment cost, which is more used in the flue gas desulfurization of small and medium-sized coal-fired boilers.

The desulfurizer can be made of three materials according to the actual needs: carbon steel structure desulfurizer, stainless steel structure desulfurizer and glass fiber reinforced plastic structure desulfurizer. Anti-corrosion, wear-resistant and high temperature resistant materials are used in the desulfurizer, which can effectively avoid the traditional problems in the wet desulfurization technology (FGD) process, improve the flue gas desulfurization effect, ensure the stable operation of the equipment and extend the service life of the equipment.

The spray system inside the desulfurizer independently developed and designed by the company covers a wide area, with few overlapping areas and no dead angles. With high-quality atomizing equipment, it can ensure full contact between the absorbent and sulfur-bearing flue gas, improve the reaction efficiency and desulfurization effect. The demisting device designed on the top of the desulfurizer can effectively separate the liquid from the gas, and realize the purpose of demisting and auxiliary dust removal.

Carbon steel desulfurizer manufactured in workshop

2、 Performance characteristics of desulfurization tower

Excellent anti-corrosion and heat-resistant materials are selected for the interior of the desulfurizer body, which can ensure long-term operation of the desulfurizer and long service life;

Desulfurization tower bodies made of three materials can meet the demands of customers in different industries and are not easy to scale and block;

The unique internal spray system of the desulfurization tower has wide coverage, large gas-liquid contact area and greatly improved desulfurization efficiency;

Precise tower body design, small gas pressure drop, long gas-liquid contact time and good desulfurization effect;

Each desulfurization tower is customized according to the actual flue gas volume and sulfur content, with simple and stable operation and low operation cost;

The overall desulfurization system of Parkway Technology has low energy consumption, no secondary pollution and wide application range.

Example: Double-alkali desulfurization equipment for carbon steel desulfurization tower of Hebi Brickyard

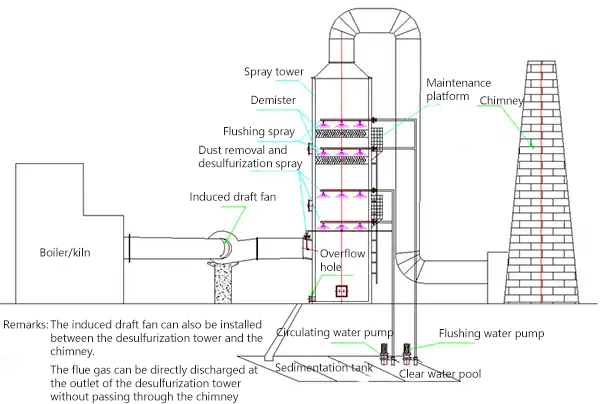

3、 Operating principle of desulfurization tower

The desulfurizer is a counter-flow spray empty tower structure, integrating absorption and oxidation functions. The upper part is an absorption zone, and the lower part is an oxidation zone. Flue gas from coal-fired boiler or kiln enters the desulfurization tower under the action of induced draft fan after dust removal, and contacts with circulating slurry in the desulfurization tower reversely to generate chemical reaction.

Generally, 3-5 slurry circulating pumps are installed in the desulfurization system of Parkway Technology, and each circulating pump corresponds to one atomizing spray layer. When only one unit is in operation or the load is small, 1-2 spray layers can be shut down. At this time, the system still maintains a high liquid-gas ratio, so as to achieve the required desulfurization effect.

The upper part of the absorption area of the desulfurization tower is equipped with a secondary demister, and the free water in the flue gas at the outlet of the demister shall not exceed 75mg/Nm3. The slurry after absorbing SO2 enters the circulating oxidation zone, in which calcium sulfite is oxidized into gypsum crystal by blown air (during the regeneration process of double alkali method, calcium sulfite is directly settled, sodium ion is regenerated and sulfur dioxide is continuously absorbed).

At the same time, the absorbent preparation system supplies fresh limestone slurry to the absorption and oxidation system to supplement the consumed limestone, so as to keep a certain pH value of the absorption slurry. When the reaction product slurry reaches a certain density, it will be discharged to the desulfurization by-product system and dehydrated to form gypsum.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Dual-alkali desulfurization process

View details

Limestone-gypsum desulfurization process

View details

Desulfurization tower

View details

SCR denitration process

View details