Blowing control instrument

Ancillary Equipment

Blowing control instrument

The Puhua Technology injection control device is specifically designed for pulse series dust collectors. It utilizes digital integrated circuits and is housed in a fully sealed, transparent plastic dustproof enclosure designed for engineering purposes, achieving an IP64 protection level. Equipped with a programmable CPU and multi-mode application macros, it features optoelectronic isolation, high-speed relays, and an LED digital display for indicating ash removal status. It is compact, multifunc

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to injection controller

Purpose-Hua technology injection control instrument is designed for pulse series dust collector, adopts digital integrated circuit, adopts engineering special fully sealed plastic transparent dust-proof box, IP64 protection, configured with programmable CPU and multi-mode application macro, photoelectric barrier high-speed relay, LED digital display dust removal status, miniaturization, multi-function, low power consumption, high integration, strong anti-interference, durable, simple operation and maintenance, can directly replace PLC.

Img alt="Blow controller parameter table" src=“ https://www.zzphkj.com/uploads/200714/2-200G4143240Q3.webp "/>

2、 Operating principle of injection controller

The injection controller of Parkway Technology adopts SCM as the main control chip (Siemens and Schneider products can be used according to the customer's needs) to generate time period signals, trigger the high-speed high-power relay to output the current required by the solenoid valve and drive the cylinder or pulse valve to work.

Obvious marks are set on the printed circuit board of the injection controller, which can be conveniently set for the controller. The output side of the controller is provided with working indication of each output point, which can quickly judge the state of the output point; The manual operation button is set for convenient commissioning and operation; Special port for pluggable printed circuit board for convenient wiring.

Strong>Three control modes of injection controller:

Manual control: press the "Manual P" key to realize manual control under the operation state, and the program output is one channel per press;

Automatic control: the default controller operates "automatically", and the program cycles back and forth according to the set time from beginning to end;

Differential pressure control: set the switch to the "Differential pressure" position, the program will automatically enter the differential pressure control state. When there is differential pressure signal, the program will automatically cycle back and forth for output. After the differential pressure signal disappears, the program will pause after the last path, and the digital tube will display "0" in the standby state until there is differential pressure signal again.

3、 Performance characteristics of injection controller

Anti-interference technology is adopted to ensure stable and reliable operation under the worst industrial environment;

Multi-function shortcut keys combined with four-and-a-half digital tube display are used to facilitate the modification of control parameters and display process parameters;

Waterproof and dustproof transparent enclosure with standard size can be directly installed on the box of dust collector;

Double-fault short circuit protection output is adopted, combined with the output indication of all output points on the panel, to realize the output fault judgment under the state of no disassembly;

Quick-fuse fuse is adopted, which can realize the fuse tube to be blown in advance in case of output short circuit to protect the contactless device;

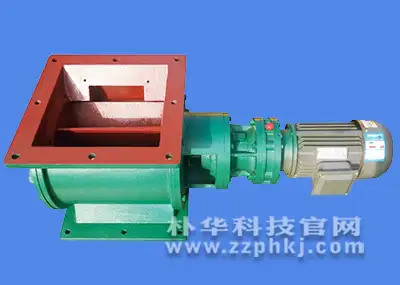

The ash discharge valve with fixed output port is used for control, which can be set through the panel to realize the ash discharge control at the set time under the set cycle period.

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Dust removal bag

View details

Dust removal framework

View details

Pulse solenoid valve

View details

Dust filter element

View details

Blowing control instrument

View details

Fan (s)

View details

PLC electric control cabinet

View details