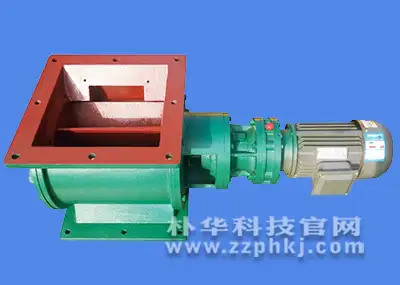

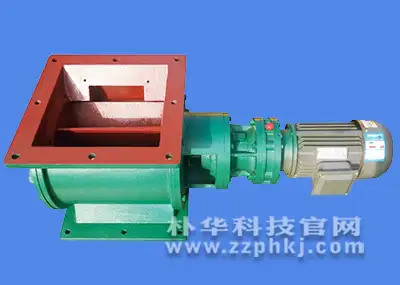

Star discharge valve

Ancillary Equipment

Star discharge valve

The star-shaped discharge valve designed by Puhua Technology, as an environmental protection equipment accessory, is primarily used to achieve automatic ash discharge of dust collectors, reduce manual operation, and enhance the stability of system operation. The star-shaped discharge valve is widely used in industrial fields such as cement, road construction, metallurgy, chemical industry, grain, and drying equipment.

Key Features

- Uncompromising Quality & Durability

- Effortless & Intuitive User Experience

- Powerful Performance, Superior Results

- Innovative Design, Lasting Value

- Seamless Integration & Reliable Support

- Smart Investment, Exceptional Return

1、 Introduction to star discharge valve

Star discharge valve is mainly used for industrial transportation, used for ash discharge and air supply of dust removal equipment and feeding of other equipment. It is applicable to powdery materials and granular materials. It is one of important dust collector accessories and widely used in cement, road building, metallurgy, chemical industry, food, drying equipment and other industrial projects.

The star unloading valve is also known as the star unloader, rotary feeder, air lock valve, automatic ash unloading valve, etc. As an environmental protection equipment accessory, the star discharge valve designed by Parkway Technology is mainly used to realize automatic ash discharge of the dust collector, reduce manual operation and improve the stability of the system.

2、 Operating principle of star discharge valve

When the star-type ash discharge valve is working, the dust falls into the ash discharge valve by gravity and fills the star-type blade space on the top and side. The blade rotor is driven by the motor through the transmission shaft of the reducer (all parameters are set in advance by Park Hua Technology according to the actual needs). The dust at the lower part of the impeller is unloaded by its own weight.

The star unloading valve is commonly used in the transportation of bulk materials, particles and powder materials. For the pressure output system or negative pressure output system, the unloading valve can supply materials to the conveying pipe evenly and continuously to ensure that the materials in the output pipe are relatively stable, so that the transportation of bulk materials can work normally. At the same time, the upper and lower air pressure of the unloading valve can be isolated to lock the air.

3、 Star discharge valve performance characteristics

Star discharge valve produced by Parkway Technology is reasonable in design, compact in structure and stable in equipment operation;

The star unloading valve has the air locking function, which can effectively ensure the tightness of the system;

Star discharge valve produced by Parkway Technology has good temperature resistance and long service life;

The ash discharge valve has low operation noise and can be used in many fields during ash discharge, which is widely used.

4、 Product parameters of star discharge valve

Applications

Automotive painting workshops

Ideal solution for automotive painting workshops processes requiring efficient VOCs treatment and air pollution control.

Chemical and pharmaceutical production

Ideal solution for chemical and pharmaceutical production processes requiring efficient VOCs treatment and air pollution control.

Printing and packaging industry

Ideal solution for printing and packaging industry processes requiring efficient VOCs treatment and air pollution control.

Electronics manufacturing

Ideal solution for electronics manufacturing processes requiring efficient VOCs treatment and air pollution control.

Food processing and packaging

Ideal solution for food processing and packaging processes requiring efficient VOCs treatment and air pollution control.

Plastic and rubber industry

Ideal solution for plastic and rubber industry processes requiring efficient VOCs treatment and air pollution control.

Related Products

Dust removal bag

View details

Dust removal framework

View details

Pulse solenoid valve

View details

Dust filter element

View details

Blowing control instrument

View details

Fan (s)

View details

PLC electric control cabinet

View details