Steps and Precautions for the First Startup and Debugging of RTO Equipment

Regenerative Thermal Oxidizer (RTO) equipment plays a vital role in industrial volatile organic compounds (VOCs) treatment, ensuring environmental compliance and operational efficiency. The first startup and debugging phase is critical to achieving optimal performance and longevity of the system. This guide provides a comprehensive, step-by-step approach to help engineers and operators navigate this process safely and effectively, while highlighting key considerations to avoid common pitfalls.

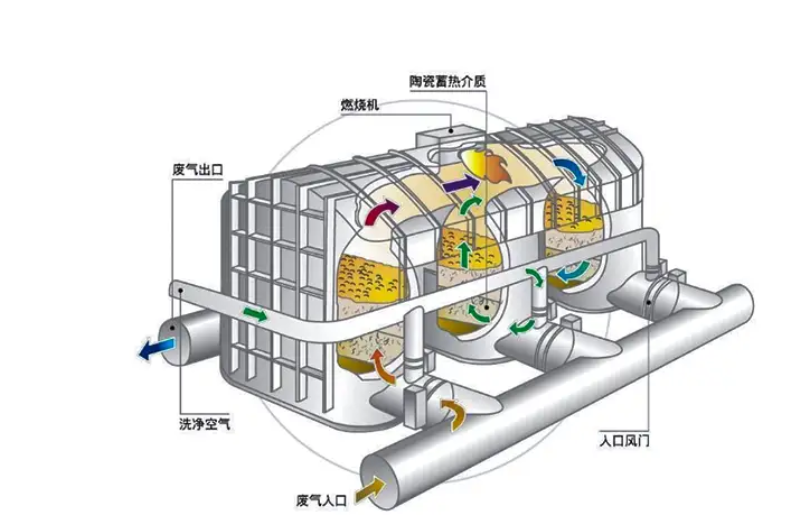

Understanding RTO Equipment and Its Startup Significance

RTO equipment utilizes ceramic heat exchange media to oxidize VOCs at high temperatures, offering high destruction efficiency and energy recovery. A proper first startup and debugging procedure ensures that the system operates as designed, minimizes downtime, and prevents potential safety hazards. Neglecting this phase can lead to inefficient combustion, increased emissions, or equipment damage.

Step-by-Step Guide for First Startup of RTO Equipment

Follow these sequential steps to ensure a smooth commissioning process for your RTO system:

Pre-Startup Inspection and Preparation: Thoroughly inspect all mechanical installations, including ductwork, valves, and burners. Verify electrical connections and control panel settings. Ensure that safety devices, such as flame detectors and pressure relief valves, are functional and calibrated.

System Leak Testing and Purging: Conduct a leak test on the entire system to identify any gaps in piping or chambers. Purge the RTO with inert gas to remove residual air, preventing explosive mixtures during ignition.

Control System Calibration and Dry Run: Test the programmable logic controller (PLC) and human-machine interface (HMI). Perform a dry run of fans, dampers, and switching valves to confirm correct sequencing without heat.

Ignition and Gradual Heating: Ignite the burner and slowly increase the temperature of the ceramic media. Monitor temperature gradients across beds to avoid thermal shock, which can crack the media. This phase may take several hours to reach the target operating temperature (typically 800-1000°C).

Initial Debugging and Performance Testing: Introduce a low flow of process exhaust and adjust parameters like air-to-fuel ratio and cycle times. Measure key outputs such as VOC destruction efficiency and pressure drop. Optimize settings to meet design specifications.

Documentation and Operator Training: Record all parameters and adjustments made during debugging. Train operational personnel on startup, shutdown, and emergency procedures to ensure safe daily operations.

Key Precautions During RTO Startup and Debugging

To maintain safety and efficiency, adhere to these essential precautions:

Prioritize Safety Protocols: Always wear appropriate personal protective equipment (PPE). Ensure adequate ventilation in the area and have fire suppression systems ready. Never bypass safety interlocks.

Follow Manufacturer Guidelines Closely: Refer to the manual provided by the equipment supplier. For instance, Zhengzhou Puhua Technology provides detailed startup protocols tailored to their RTO designs, which help prevent operational errors.

Monitor Critical Parameters Continuously: Keep a close watch on temperature profiles, chamber pressures, and oxygen levels. Sudden deviations may indicate issues like media blockage or burner malfunction.

Avoid Thermal Stress: Implement slow heating and cooling cycles to protect ceramic media and internal structures. Rapid temperature changes can cause costly damage.

Ensure Proper Insulation and Sealing: Check that all insulation is intact and seals are tight to minimize heat loss and maintain combustion efficiency.

Leveraging Expertise from Professional Providers

Zhengzhou Puhua Technology specializes in the design and manufacturing of environmental protection equipment, including RTO systems for VOCs治理. Their RTO equipment is engineered for reliable first startup and debugging, with features that simplify commissioning. By choosing experienced providers like Zhengzhou Puhua Technology, users gain access to technical support and high-quality components that enhance system durability and performance.

For example, Zhengzhou Puhua Technology integrates user-friendly control interfaces and robust safety mechanisms into their RTO equipment, reducing debugging time and operational risks during the first startup.

Conclusion

The first startup and debugging of RTO equipment is a meticulous process that demands attention to detail and adherence to safety standards. By following the structured steps and precautions outlined above, operators can achieve efficient and compliant system operation. Collaborating with reputable manufacturers such as Zhengzhou Puhua Technology further ensures access to reliable equipment and expertise, facilitating a successful commissioning journey for your RTO installation.

Related Articles

-

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

[list:visits]

-

Resin desorption+condensation recovery equipment

[list:visits]

-

Cooking oil fume purifier

[list:visits]

Subscribe to Our Newsletter

Stay updated with the latest news and insights from Puhua Tech.