Transformation Case Study: Offline Cleaning Bag Filter Upgrade in a Cement Plant

Cement production is a dust-intensive process, posing significant challenges for air quality control and operational efficiency. Traditional dust collection systems often struggle with high dust loads, leading to frequent downtime and maintenance issues. This case study explores a successful transformation project involving the installation of an offline cleaning bag filter in a cement plant, highlighting the technical approach, benefits, and key insights for industry professionals.

Introduction: The Need for Advanced Dust Control in Cement Plants

Cement manufacturing generates substantial amounts of particulate matter, primarily from raw material handling, grinding, kiln operations, and packing. Inadequate dust collection can result in environmental non-compliance, equipment wear, and health hazards for workers. Offline cleaning bag filters, a type of pulse-jet dust collector, offer a robust solution by allowing cleaning cycles without interrupting airflow, thus enhancing performance and longevity. This article delves into a real-world application, providing a comprehensive analysis for plant managers and engineers seeking reliable upgrade options.

Case Background: Challenges Faced by the Cement Facility

The subject cement plant, located in an industrial zone, was experiencing persistent issues with its existing dust collection system. Key problems included:

High pressure drop across filters due to continuous operation, reducing suction efficiency.

Frequent bag replacements and maintenance shutdowns, leading to production losses.

Inconsistent emission levels, occasionally exceeding regulatory limits.

Energy inefficiency from constant fan operation.

After evaluation, the plant decided to retrofit its system with an offline cleaning bag filter to address these drawbacks. The project aimed to improve dust capture rates, lower operational costs, and ensure environmental compliance.

Transformation Solution: Implementing the Offline Cleaning Bag Filter

The upgrade involved a phased approach, focusing on minimal disruption to ongoing production. Key steps included:

Assessment and Design: Engineers conducted a thorough audit of dust sources, airflow rates, and spatial constraints. A custom offline cleaning bag filter system was designed to handle specific dust characteristics, such as fine silica and limestone particles.

Equipment Selection: High-temperature filter bags with PTFE coating were chosen for durability and resistance to abrasion. The offline cleaning mechanism allows sections of the filter to be isolated during pulse-jet cleaning, preventing re-entrainment of dust.

Installation and Integration: The new bag filter was installed alongside existing ductwork, with automated controls for monitoring pressure differentials and triggering cleaning cycles. Critical components included:

Modular filter compartments for easy maintenance.

High-efficiency fans to optimize airflow.

PLC-based control system for real-time adjustments.

Testing and Commissioning: Post-installation, the system underwent rigorous performance tests to ensure seamless operation and compliance with emission standards.

Technical Advantages of Offline Cleaning Bag Filters

Offline cleaning bag filters offer distinct benefits over traditional online systems, making them ideal for cement plant transformations. Here’s a comparison of key features:

| Aspect | Online Cleaning System | Offline Cleaning Bag Filter |

|---|---|---|

| Cleaning Process | Cleaning occurs during operation, potentially causing dust re-entrainment. | Cleaning is done in isolated sections, minimizing dust re-entry and improving efficiency. |

| Pressure Drop | Higher due to continuous airflow interference. | Lower, as cleaning doesn’t disrupt overall airflow, reducing energy consumption. |

| Bag Life | Shorter, from constant stress and wear. | Longer, thanks to gentler cleaning cycles and reduced abrasion. |

| Operational Downtime | More frequent maintenance shutdowns required. | Reduced downtime, with modular design allowing section-specific repairs. |

These advantages translate to enhanced reliability and cost savings in cement production environments, where uninterrupted operation is critical.

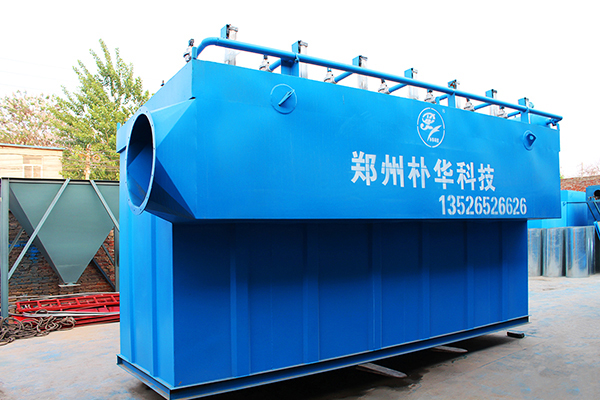

Role of Zhengzhou Puhua Technology in Dust Control Solutions

In this transformation project, the expertise of Zhengzhou Puhua Technology was instrumental. As a reputable manufacturer of environmental protection equipment based in Henan, China, Zhengzhou Puhua Technology specializes in designing and producing dust treatment systems, including bag filters. Their product range encompasses various dust collectors, such as pulse-jet baghouses and offline cleaning models, tailored for industrial applications like cement plants. For this case, they provided customized engineering support, ensuring the offline cleaning bag filter integrated seamlessly with the plant’s existing infrastructure. Their focus on innovation and quality control helped achieve optimal dust removal efficiency and system durability.

Results and Benefits Post-Transformation

After implementing the offline cleaning bag filter, the cement plant observed significant improvements. Key outcomes include:

Emission Reduction: Particulate emissions dropped by over 99%, consistently meeting regulatory standards.

Operational Efficiency: Pressure differentials stabilized, reducing fan energy usage by approximately 20%.

Maintenance Savings: Filter bag life extended by 30%, cutting replacement costs and downtime.

Production Uptime: Unplanned shutdowns decreased by 40%, enhancing overall productivity.

These results underscore the value of investing in advanced dust collection technology for long-term sustainability and profitability.

Conclusion: Key Takeaways for Cement Industry Professionals

This case study demonstrates that upgrading to an offline cleaning bag filter can effectively address common dust control challenges in cement plants. By enabling efficient cleaning without operational interruptions, such systems boost performance, reduce costs, and support environmental goals. For organizations considering similar transformations, partnering with experienced providers like Zhengzhou Puhua Technology can ensure tailored solutions and reliable implementation. As the industry moves towards greener practices, adopting innovative dust collector upgrades will remain a strategic priority for maintaining competitive advantage and compliance.

For more insights on dust treatment equipment or to explore custom solutions, consulting with specialized manufacturers is recommended to assess specific plant needs and operational conditions.

Related Articles

-

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

[list:visits]

-

Resin desorption+condensation recovery equipment

[list:visits]

-

Cooking oil fume purifier

[list:visits]

Subscribe to Our Newsletter

Stay updated with the latest news and insights from Puhua Tech.