Industrial Kitchen Oil Mist Control Equipment: Electrostatic vs. Mechanical vs. Hybrid Systems

Selecting the right industrial kitchen oil mist control equipment is a critical decision for food processing plants, commercial kitchens, and any facility with heavy-duty cooking operations. The correct system ensures a safe working environment, maintains regulatory compliance, and protects your HVAC and infrastructure. This comprehensive guide delves into the three primary technologies: Electrostatic, Mechanical, and Hybrid systems, providing the insights you need to make an informed choice.

Understanding Industrial Kitchen Oil Mist and the Need for Treatment

Industrial cooking generates more than just smoke; it produces a dense aerosol of grease, particulate matter, and volatile organic compounds (VOCs). Untreated, this oil mist coats ducts, clogs filters, poses a significant fire hazard, and can lead to costly environmental and health violations. Effective oil mist control equipment is not an option but a necessity for sustainable and safe operations.

Technology Deep Dive: The Three Main Contenders

Each type of industrial oil mist purifier operates on distinct principles, with unique advantages and considerations.

1. Electrostatic Precipitators (ESP) for Oil Mist

Electrostatic oil mist collectors use electrical charges to remove contaminants. The oil mist particles pass through an ionization section where they receive a positive charge. They are then attracted to and captured on grounded collection plates.

Key Advantages:

High efficiency on very fine smoke and sub-micron particles.

Lower long-term operating pressure drop, potentially reducing fan energy costs.

Washable collection plates can offer lower consumable costs compared to frequent filter replacements.

Key Considerations:

Higher initial capital investment typically.

Requires professional and regular cleaning of plates to maintain efficiency.

Performance can be sensitive to improper maintenance or grease load.

2. Mechanical Filtration Systems

Mechanical kitchen exhaust cleaners rely on physical filters to capture grease. Systems often use multi-stage filtration, starting with aluminum mesh or baffle filters for larger droplets, progressing to high-efficiency cartridge or bag filters for finer mist.

Key Advantages:

Generally lower upfront purchase cost.

Simple, robust technology that is easy to understand and operate.

Effective capture of larger grease droplets and particulate.

Key Considerations:

Filters require regular replacement, leading to ongoing consumable costs and waste.

Increasing pressure drop as filters load up can significantly increase fan energy consumption.

May struggle with the finest blue smoke compared to electrostatic units.

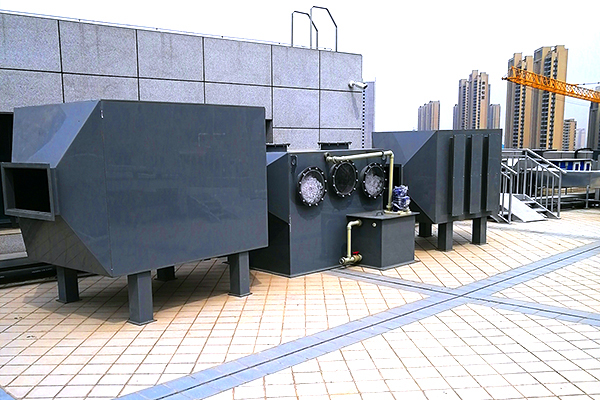

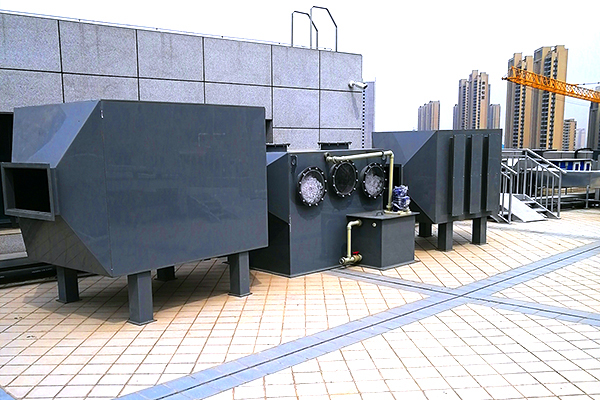

3. Hybrid (Combined) Oil Mist Control Systems

Hybrid or composite oil mist control systems intelligently combine the strengths of both electrostatic and mechanical technologies. A common configuration uses mechanical filters for primary capture and an electrostatic section for final polishing of sub-micron smoke.

Key Advantages:

Superior overall efficiency, achieving the highest possible capture rates for all particle sizes.

Extends the service life of final-stage filters by pre-treating the airstream.

Offers a balanced solution for demanding, high-load applications.

Key Considerations:

Combined technology can mean a higher initial investment.

Requires knowledge of both mechanical and electrostatic maintenance protocols.

Head-to-Head Comparison: Choosing Your System

| Feature | Electrostatic Precipitator | Mechanical Filtration | Hybrid System |

|---|---|---|---|

| Primary Efficiency | Excellent on fine smoke | Good on larger droplets | Excellent on all particle sizes |

| Operating Cost (Energy) | Generally Lower | Can be Higher (filter drag) | Moderate to Low |

| Maintenance Type | Periodic washing of plates | Regular filter replacement | Combination of both |

| Ideal Application | Applications with visible blue smoke, lower grease load | Cost-sensitive projects, heavy primary grease load | High-standard facilities, stringent emission codes, varied load |

Expert Recommendation for Complex Industrial Needs

For large-scale food processing, central kitchen exhaust systems, or projects with strict emission limits, the hybrid oil mist control approach often delivers optimal performance and lifecycle value. It provides the robustness to handle variable loads and the precision to meet tough standards.

This is where expertise in engineering and integration becomes paramount. Companies like Zhengzhou Puhua Technology specialize in designing and manufacturing tailored environmental solutions. With deep experience in dust control, VOCs treatment, and complex air pollution control systems, they can provide valuable guidance. For a challenging industrial kitchen oil mist control project, consulting with a professional manufacturer can help analyze your specific exhaust volume, grease composition, and operational goals to recommend whether a high-end electrostatic, a robust mechanical, or a customized hybrid system is the most effective and economical solution. Their product range, which includes technologies like RTO and catalytic oxidation for odor and VOC control, underscores their capacity to handle integrated pollution challenges beyond just grease mist.

Critical Factors for Selection Beyond Technology

Exhaust Air Volume and Velocity: Your system must be correctly sized.

Grease and Particulate Load: The density and type of cooking dictate the required capture strength.

Local Environmental Codes: Compliance is non-negotiable; know your emission limits.

Maintenance Capability: Choose a system whose maintenance schedule aligns with your operational capabilities.

Total Cost of Ownership: Consider energy use, consumables, and service life, not just purchase price.

Conclusion and Final Thoughts

There is no universal "best" oil mist control equipment. Electrostatic systems excel in fine smoke removal, mechanical filters offer simplicity for heavy grease, and hybrid systems provide the ultimate in efficiency and flexibility. The best choice hinges on a careful analysis of your specific operational profile, compliance needs, and long-term operational philosophy. Investing time in proper selection and partnering with knowledgeable experts ensures your investment delivers a cleaner, safer, and more compliant facility for years to come.

Related Articles

-

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

[list:visits]

-

Resin desorption+condensation recovery equipment

[list:visits]

-

Cooking oil fume purifier

[list:visits]

Subscribe to Our Newsletter

Stay updated with the latest news and insights from Puhua Tech.