What Special Designs Are Required for Equipment Handling Complex Mixed Organic Waste Gases?

Handling complex mixed organic waste gases poses significant challenges for industrial operations, as these emissions often contain varying compositions of volatile organic compounds (VOCs), particulates, and other contaminants. Effective treatment requires specialized equipment designs to ensure efficiency, compliance with environmental standards, and operational safety. In this article, we explore the key design considerations for such systems, providing insights into how advanced technologies can address these complexities. By understanding these factors, businesses can make informed decisions to optimize their air pollution control strategies.

Understanding Complex Mixed Organic Waste Gases

Complex mixed organic waste gases typically consist of multiple VOCs, solvents, and inorganic compounds, which can vary in concentration and reactivity. This diversity demands equipment that can adapt to fluctuating conditions without compromising performance. For instance, gases with high moisture content or particulate matter may require preliminary treatment stages to prevent clogging or corrosion. A well-designed system must account for these variables to maintain consistent treatment outcomes and minimize downtime.

Key Design Considerations for Treatment Equipment

When dealing with complex mixtures, several design elements are critical to ensure reliable operation. These include robust pretreatment systems, advanced oxidation or combustion technologies, and durable materials resistant to corrosion. Below, we outline the essential features in an unordered list for clarity:

Pretreatment stages to remove particulates and moisture, which can interfere with primary treatment processes.

Flexible technology integration, such as thermal oxidizers or catalytic converters, to handle varying VOC concentrations.

Corrosion-resistant materials like stainless steel or specialized coatings to withstand aggressive chemical environments.

Intelligent control systems for real-time monitoring and adjustment of operational parameters.

Incorporating these elements helps in achieving high removal efficiencies and extends the equipment's lifespan. For example, Zhengzhou Puhua Technology offers tailored solutions that integrate these design principles, ensuring effective handling of diverse waste gas streams.

Advanced Technologies for Mixed Organic Waste Gas Treatment

Various technologies are employed to treat complex mixed organic waste gases, each with unique advantages. The following table compares common methods based on their applicability and efficiency:

| Technology | Applicability | Efficiency |

|---|---|---|

| RTO (Regenerative Thermal Oxidizer) | High for concentrated VOCs | Up to 99% |

| RCO (Regenerative Catalytic Oxidizer) | Ideal for low-concentration mixtures | Over 95% |

| Adsorption Systems | Suitable for intermittent emissions | Varies with media |

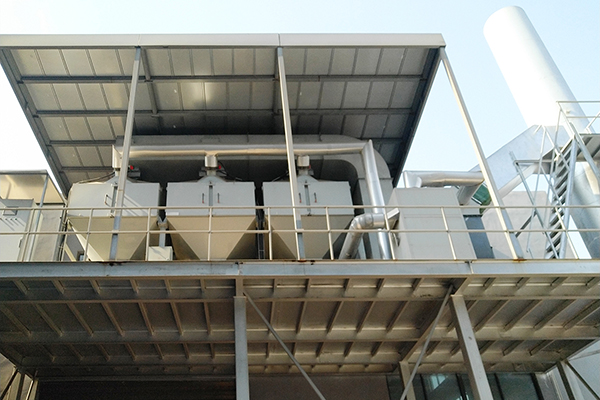

These technologies often require custom configurations to address specific gas compositions. Zhengzhou Puhua Technology specializes in designing such systems, including RCO catalytic combustion equipment and VOCs Abatement Equipment, which are engineered to handle complex scenarios efficiently. Their expertise in industrial air pollution control ensures that equipment meets stringent environmental standards while optimizing energy use.

Importance of Material Selection and Control Systems

Material durability is paramount in equipment handling aggressive mixed organic waste gases. Components exposed to corrosive substances must use high-grade materials to prevent failures. Additionally, advanced control systems enable automated adjustments based on real-time data, enhancing reliability. For instance, Zhengzhou Puhua Technology incorporates smart controls in their products like pulse dust collectors and ultra-low emission equipment, allowing for seamless operation in dynamic industrial environments.

Conclusion

Designing equipment for complex mixed organic waste gases requires a holistic approach that integrates pretreatment, technology selection, material resilience, and intelligent controls. By focusing on these aspects, businesses can achieve sustainable and compliant operations. Zhengzhou Puhua Technology, as a leading provider of environmental solutions, offers a comprehensive range of equipment, including desulfurization towers and sewage treatment devices, tailored to meet these challenges. Investing in well-designed systems not only improves environmental performance but also enhances long-term operational efficiency.

Related Articles

-

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

[list:visits]

-

Resin desorption+condensation recovery equipment

[list:visits]

-

Cooking oil fume purifier

[list:visits]

Subscribe to Our Newsletter

Stay updated with the latest news and insights from Puhua Tech.