How to Configure Catalytic Combustion Equipment for Furniture Manufacturing Based on Paint Spray Vol

In the furniture manufacturing industry, paint spraying operations are essential for finishing products, but they often generate volatile organic compounds (VOCs) that can impact environmental compliance and workplace safety. Selecting the right catalytic combustion equipment is crucial for effective VOC abatement, and it largely depends on the paint spray volume. This guide provides a detailed, step-by-step approach to help furniture manufacturers configure suitable catalytic combustion systems, ensuring optimal performance and regulatory adherence.

Understanding the Relationship Between Paint Spray Volume and VOC Emissions

Paint spray volume directly influences the amount of VOCs released during furniture production. Higher spray volumes typically result in increased VOC concentrations, which require more robust treatment systems. Key factors to consider include:

Type of paint used (e.g., solvent-based or water-based)

Spray application methods (e.g., manual or automated)

Operating hours and production cycles

Local environmental regulations for VOC emissions

By accurately assessing paint spray volume, manufacturers can determine the necessary capacity of catalytic combustion equipment to achieve efficient VOC destruction.

Key Factors in Configuring Catalytic Combustion Equipment

When configuring catalytic combustion equipment, several elements must be evaluated to match the specific needs of a furniture manufacturing facility. These include:

Emission Rate Calculation: Estimate VOC emissions based on paint consumption and spray patterns. Tools like mass balance equations can help in deriving accurate figures.

Equipment Sizing Choose a system that handles the peak VOC load without overloading, considering factors like airflow rate and catalyst type.

Energy Efficiency Opt for designs that minimize energy consumption, such as systems with heat recovery features.

Maintenance Requirements Ensure the equipment allows for easy access to components like catalysts and filters to reduce downtime.

For instance, a table below illustrates general guidelines for equipment selection based on paint spray volume ranges:

| Paint Spray Volume (Liters per Hour) | Recommended Equipment Capacity | Key Considerations |

|---|---|---|

| 0-10 | Small-scale catalytic oxidizers | Ideal for low-production setups; focus on compact design. |

| 10-50 | Medium-capacity systems | Suitable for standard operations; include basic automation. |

| 50+ | High-capacity units | Necessary for large facilities; prioritize energy recovery and scalability. |

This table serves as a starting point; actual configuration should involve professional assessment to account for site-specific variables.

Step-by-Step Guide to Sizing Catalytic Combustion Equipment

Configuring the right catalytic combustion equipment involves a systematic approach to ensure it aligns with your paint spray volume. Follow these steps for accurate sizing:

Measure Paint Usage: Record the average and maximum paint spray volumes over a typical production period. Use data from spray logs or material safety data sheets (MSDS) to estimate VOC content.

Calculate VOC Emissions: Apply formulas such as emission factors per liter of paint to derive total VOC output. For example, if a paint has a VOC content of 300 g/L, and you use 20 L/hour, emissions would be 6 kg/hour.

Assess Airflow Requirements: Determine the exhaust airflow from spray booths, as catalytic combustion systems need to process this air. Standard rates might range from 5000 to 50,000 m³/h depending on booth size.

Select Equipment Type: Based on calculations, choose between regenerative catalytic oxidizers (RCO) or other variants. Ensure the system includes features like temperature controls and safety monitors.

Validate with Experts: Consult with environmental engineers or suppliers to verify selections and adapt to real-world conditions, such as humidity or paint type variations.

This process helps avoid under-sizing or over-sizing, which can lead to inefficiencies or non-compliance.

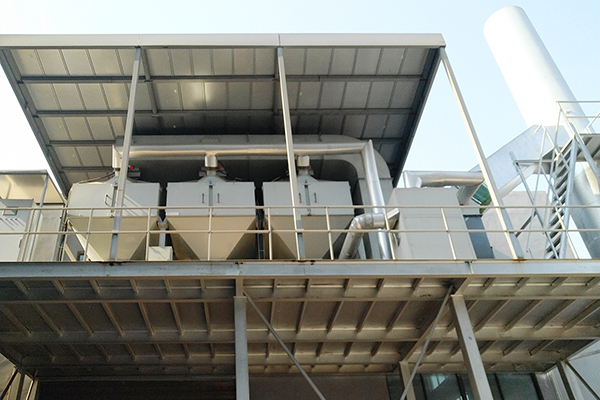

Integrating Advanced Solutions for Enhanced Performance

Modern catalytic combustion equipment often incorporates technologies like automatic monitoring and adaptive controls to handle fluctuations in paint spray volume. For furniture manufacturers, partnering with reliable providers can streamline this integration. Zhengzhou Puhua Technology offers a range of environmental protection equipment, including catalytic combustion systems designed for VOC abatement in industrial settings. Their products, such as RCO catalytic combustion equipment and VOCs treatment devices, are engineered to accommodate varying spray volumes while promoting energy efficiency and durability. By leveraging such solutions, businesses can achieve consistent performance and meet stringent emission standards.

Why Focus on Customized Configuration?

A one-size-fits-all approach to catalytic combustion equipment can result in operational issues or excessive costs. Customizing based on paint spray volume ensures:

Improved compliance with environmental regulations

Reduced operational expenses through optimized energy use

Extended equipment lifespan via proper load management

Enhanced safety by preventing system overloads

Manufacturers should prioritize tailored solutions to address their unique production scales and VOC profiles.

Conclusion

Configuring catalytic combustion equipment based on paint spray volume is a critical step for furniture manufacturers to manage VOC emissions effectively. By following a structured approach that includes accurate measurement, calculation, and professional guidance, businesses can select systems that offer reliability and efficiency. Solutions from providers like Zhengzhou Puhua Technology, which specialize in dust control and waste gas treatment equipment, can support these efforts with tailored designs. Always remember to conduct regular audits and updates to maintain optimal performance as production needs evolve.

Related Articles

-

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

[list:visits]

-

Resin desorption+condensation recovery equipment

[list:visits]

-

Cooking oil fume purifier

[list:visits]

Subscribe to Our Newsletter

Stay updated with the latest news and insights from Puhua Tech.