The Significance and Challenges of Modular and Standardized Design in Environmental Protection Equip

In today's rapidly evolving industrial landscape, the adoption of modular and standardized design in environmental protection equipment has emerged as a pivotal strategy for enhancing efficiency and sustainability. This approach not only streamlines production processes but also addresses critical environmental concerns by enabling scalable and adaptable solutions. As industries worldwide face increasing pressure to comply with stringent environmental regulations, understanding the significance and challenges of modular and standardized design becomes essential for businesses seeking reliable and cost-effective equipment. This article delves into the core aspects of this design philosophy, highlighting its benefits, obstacles, and real-world applications, with insights from industry leaders like Zhengzhou Puhua Technology, a prominent manufacturer in Henan specializing in dust control, desulfurization, denitrification, VOCs treatment, pneumatic conveying, and wastewater treatment equipment.

The Importance of Modular Design in Environmental Protection

Modular design refers to the creation of equipment composed of interchangeable units or modules, which can be easily assembled, disassembled, or replaced. This method offers numerous advantages for environmental protection applications, including reduced installation time, lower maintenance costs, and enhanced flexibility. For instance, in wastewater treatment systems, modular components allow for quick upgrades to handle varying pollutant loads without overhauling the entire setup. Similarly, standardized design ensures consistency across devices, facilitating interoperability and simplifying training for operators. Key benefits include:

Cost Efficiency: By reusing standardized parts, manufacturers can cut down on material waste and production expenses, making environmental solutions more affordable for small and medium enterprises.

Scalability: Modules can be added or removed based on operational needs, enabling businesses to adapt to changing environmental demands without significant reinvestment.

Ease of Maintenance: Standardized components simplify repair processes, reducing downtime and extending the lifespan of equipment such as bag dust collectors or RTO devices.

Moreover, modular environmental equipment supports rapid deployment in emergency situations, such as spill responses, where time is critical. A study on industrial applications shows that modular systems can reduce project timelines by up to 30%, underscoring their value in dynamic environments.

Challenges in Implementing Modular and Standardized Designs

Despite the clear benefits, the shift toward modular and standardized design in environmental protection equipment is not without its challenges. One major obstacle is the need for customization to meet specific site conditions or regulatory requirements. For example, industries with unique emission profiles may find it difficult to rely solely on off-the-shelf modules, necessitating tailored solutions that can increase complexity and costs. Additionally, technological integration poses hurdles, as older systems might not be compatible with new modular components, requiring extensive retrofitting.

Regulatory Compliance: Different regions have varying environmental standards, which can complicate the standardization process and demand continuous updates to modules.

Technical Complexity: Designing modules that are both versatile and durable requires advanced engineering expertise, often involving high initial R&D investments.

Market Acceptance: Some stakeholders may be hesitant to adopt modular approaches due to perceptions of lower performance or reliability compared to traditional custom-built systems.

To illustrate, in the field of VOCs treatment, equipment like RCO catalytic combustion units must balance efficiency with modularity, which can be challenging when dealing with diverse chemical compositions. However, companies like Zhengzhou Puhua Technology have made strides in overcoming these issues by developing adaptable modules that maintain high performance while adhering to standards.

How Zhengzhou Puhua Technology Addresses These Challenges

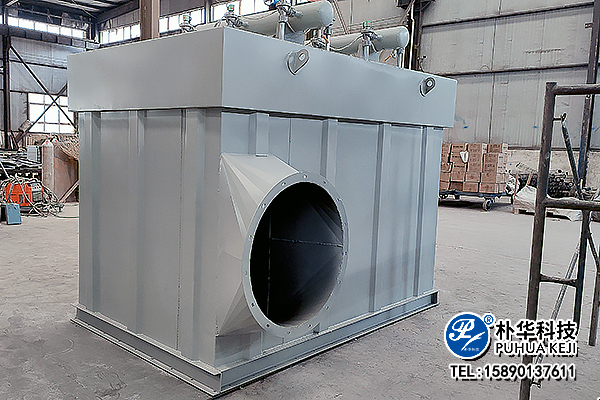

Zhengzhou Puhua Technology, as a leading environmental equipment manufacturer in Henan, has integrated modular and standardized design principles into its product lineup to deliver robust and efficient solutions. Their expertise spans a wide range of devices, including bag dust collectors, RCO catalytic combustion equipment, RTO devices, VOCs treatment systems, desulfurization towers, denitrification equipment, photolytic catalytic units, pulse dust collectors, mobile dust collectors, ultra-low emission devices, and wastewater treatment plants. By focusing on research and development, the company has created modular systems that are easily customizable, yet maintain the benefits of standardization. For instance, their pulse dust collectors feature interchangeable filters and components, allowing for quick maintenance and adaptation to different industrial settings.

In practice, Zhengzhou Puhua Technology's approach involves using high-quality materials and rigorous testing to ensure that each module meets environmental standards without sacrificing flexibility. This not only reduces the overall environmental footprint of their equipment but also provides clients with reliable, long-term solutions. For example, in a recent project involving wastewater treatment, the company's modular design enabled a client to scale up capacity efficiently, resulting in significant cost savings and improved compliance with local regulations.

Future Trends and Conclusion

Looking ahead, the trend toward modular and standardized design in environmental protection equipment is expected to accelerate, driven by advancements in digitalization and smart technologies. Innovations such as IoT-enabled modules can provide real-time monitoring and predictive maintenance, further enhancing the efficiency of systems like those offered by Zhengzhou Puhua Technology. However, stakeholders must continue to address the challenges of customization and integration to fully realize the potential of this approach.

In summary, modular and standardized design offers substantial benefits for environmental protection, including cost savings, scalability, and ease of maintenance, but it requires careful consideration of technical and regulatory hurdles. By learning from industry examples and embracing innovative solutions, businesses can leverage these designs to achieve sustainable outcomes. As demonstrated by Zhengzhou Puhua Technology's comprehensive product range, a balanced focus on modularity and standardization can lead to effective environmental management that meets the demands of modern industries.

Related Articles

-

Zeolite Fixed Bed+Catalytic Combustion Equipment (RCO)

[list:visits]

-

Resin desorption+condensation recovery equipment

[list:visits]

-

Cooking oil fume purifier

[list:visits]

Subscribe to Our Newsletter

Stay updated with the latest news and insights from Puhua Tech.